Page 85 - Know and Understand Centrifugal Pumps

P. 85

Know and Understand Centrifugal Pumps

The operator of a car would know the limits of his automobile. He would or should

know if the car is capable of operating safely before launching out on a cross-country

trip at highway speeds. He should know how much weight the car can carry safely in

the trunk. He should have a general idea if he’s getting the expected gasoline mileage

from his car. Right? Likewise, the process engineer (and operators) of an industrial

pump should know the operating window of the pump. RIGHT?

In the numerator we have the speed and the flow. If we were comparing

similar pumps into an application, these multiplied numbers would

mostly be a constant. In the denominator we have the NPSHr of the

pump (or competing pumps under comparison for an application). As

the NPSHr of the pump goes down, the Nss value rises. As the Nss

value increases, the operating window of the pump narrows.

Some pump companies will promote and tout their low Nss values.

Sometimes a specification engineer will establish a maximum Nss limit

for quoted pumps. Let’s consider these examples of operating

parameters of pumps, and determine the Nss. These values are lifted

from the pump performance curves at the BEP.

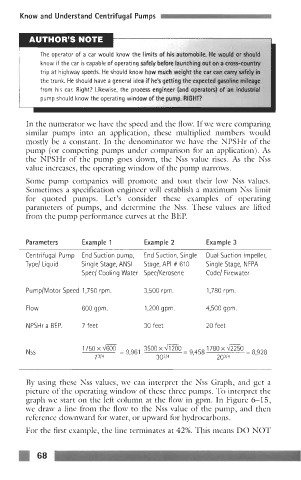

Para meters Example 1 Example 2 Example 3

Centrifugal Pump End Suction pump, End Suction, Single Dual Suction Impeller,

Type/ Liquid Single Stage, ANSI Stage, API # 610 Single Stage, NFPA

Spec/ Cooling Water SpeclKerosene Code/ Firewater

Pump/Motor Speed 1,750 rpm. 3,500 rpm. 1,780 rpm.

Flow 600 gprn. 1,200 gprn. 4,500 gpm.

NPSHr a BEP. 7 feet 30 feet 20 feet

1750 x 4600 = 9,961 3500 x

Nss = 9,458 1780 x G O = 8,928

73/4 303/4 203/4

By using these Nss values, we can interpret the Nss Graph, and get a

picture of the operating window of these three pumps. To interpret the

graph we start on the left column at the flow in gpm. In Figure 6-15,

we draw a line from the flow to the Nss value of the pump, and then

reference downward for water, or upward for hydrocarbons.

For the first example, the line terminates at 42%. This means DO NOT