Page 265 - Lean six sigma demystified

P. 265

Chapter 7 Redu C ing Va R iation with Six Sigm a 243

Process Capability Indicators Improvement Objective

If Cp is greater than Cpk Center the process

Cp > Cpk

If Cp is approximately equal to Cpk and both are Reduce variation

less than 1.33

Cp = Cpk < 1.33

Root Cause Analysis

Again, you can use the Ishikawa (fishbone) diagram to analyze the root

causes of (1) off-center or (2) excess variation. Remember, common causes

of variation may require systemic changes to achieve your capability goals.

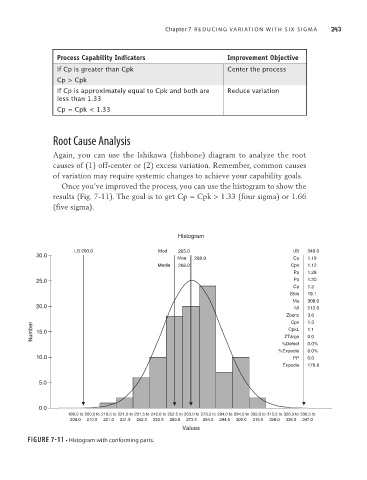

Once you’ve improved the process, you can use the histogram to show the

results (Fig. 7-11). The goal is to get Cp = Cpk > 1.33 (four sigma) or 1.66

(five sigma).

Histogram

LS 200.0 Mod 265.0 US 346.0

30.0

Mea 268.9 Cp 1.19

Media 268.0 Cpk 1.12

Pp 1.28

25.0 Pp 1.20

Cp 1.2

Stde 19.1

Ma 308.0

20.0 Mi 212.0

Zbenc 3.6

1.3

Cpk

Number 15.0 ZTarge 1.1

CpkL

0.0

%Defect 0.0%

%Expecte 0.0%

10.0 PP 0.0

Expecte 176.8

5.0

0.0

189.5 to 200.0 to 210.5 to 221.0 to 231.5 to 242.0 to 252.5 to 263.0 to 273.5 to 284.0 to 294.5 to 305.0 to 315.5 to 326.0 to 336.5 to

200.0 210.5 221.0 231.5 242.0 252.5 263.0 273.5 284.0 294.5 305.0 315.5 326.0 336.5 347.0

Values

FIgure 7-11 • Histogram with conforming parts.