Page 127 - Materials Chemistry, Second Edition

P. 127

Life Cycle Assessment: Principles, Practice and Prospects

114

Infrastructure

Farm

and minor services,

establishment

ancillary materials

Agricultural

machinery Energy and

production and Field preparation ancillary materials

operation

Fertiliser and Planting, fertilising Across life cycle

pesticide and pesticide

production application

Crop growing Corn grain

and harvesting separation

Grain transport

Plowing stubble to product

back into field

manufacture

Processing grain

to corn chips

Packaging and Consumption of

delivery corn chips

Disposal of

packaging

Landfill

System boundary for LCA

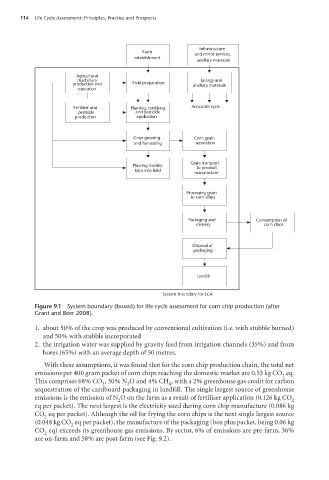

Figure 9.1 System boundary (boxed) for life cycle assessment for corn chip production (after

Grant and Beer 2008).

1. about 50% of the crop was produced by conventional cultivation (i.e. with stubble burned)

and 50% with stubble incorporated

2. the irrigation water was supplied by gravity feed from irrigation channels (35%) and from

bores (65%) with an average depth of 50 metres.

With these assumptions, it was found that for the corn chip production chain, the total net

emissions per 400 gram packet of corn chips reaching the domestic market are 0.53 kg CO eq.

2

This comprises 68% CO , 30% N O and 4% CH , with a 2% greenhouse gas credit for carbon

2 2 4

sequestration of the cardboard packaging in landfill. The single largest source of greenhouse

emissions is the emission of N O on the farm as a result of fertiliser application (0.126 kg CO

2 2

eq per packet). The next largest is the electricity used during corn chip manufacture (0.086 kg

CO eq per packet). Although the oil for frying the corn chips is the next single largest source

2

(0.048 kg CO eq per packet), the manufacture of the packaging (box plus packet, being 0.06 kg

2

CO eq) exceeds its greenhouse gas emissions. By sector, 6% of emissions are pre-farm, 36%

2

are on-farm and 58% are post-farm (see Fig. 9.2).

100804•Life Cycle Assessment 5pp.indd 114 17/02/09 12:46:22 PM