Page 163 - Materials Chemistry, Second Edition

P. 163

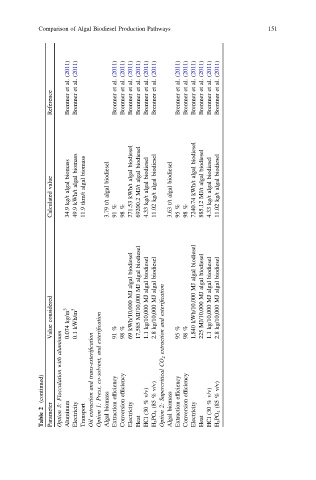

Comparison of Algal Biodiesel Production Pathways 151

(2011) (2011) (2011) (2011) (2011) (2011) (2011) (2011) (2011) (2011) (2011) (2011) (2011) (2011)

al. al. al. al. al. al. al. al. al. al. al. al. al. al.

et et et et et et et et et et et et et et

Reference Brentner Brentner Brentner Brentner Brentner Brentner Brentner Brentner Brentner Brentner Brentner Brentner Brentner Brentner

biomass biomass biomass biodiesel biodiesel algal biodiesel biodiesel biodiesel biodiesel biodiesel algal biodiesel biodiesel biodiesel

value algal algal algal algal kWh/t algal MJ/t algal algal algal kWh/t algal MJ/t algal algal

Calculated kg/t 34.9 kWh/t 49.9 tkm/t 11.9 t/t 3.79 % 91 % 98 271.53 69200.2 kg/t 4.33 kg/t 11.02 t/t 3.63 % 95 % 98 7240.74 885.12 kg/t 4.33 kg/t 11.02

biodiesel biodiesel biodiesel biodiesel biodiesel biodiesel biodiesel biodiesel

algal algal MJ algal algal algal MJ algal algal algal

MJ MJ MJ esterification MJ MJ MJ

considered kg/m 3 kWh/m 3 kWh/10,000 MJ/10,000 kg/10,000 kg/10,000 kWh/10,000 MJ/10,000 kg/10,000 kg/10,000

Value 0.074 0.1 esterification % 91 % 98 69 17,585 1.1 2.8 and % 95 % 98 1,840 225 1.1 2.8

aluminum and extraction

with trans-esterification co-solvent, CO 2

(continued) Flocculation and Press, efficiency efficiency v/v) v/v) % Supercritical efficiency efficiency v/v) v/v) %

2 3: Aluminum extraction 1: biomass Conversion % (30 (85 2: biomass Conversion % (30 (85

Table Parameter Option Electricity Transport Oil Option Algal Extraction Electricity Heat HCl H 3 PO 4 Option Algal Extraction Electricity Heat HCl H 3 PO 4