Page 202 - Materials Chemistry, Second Edition

P. 202

190 B. Ruggeri et al.

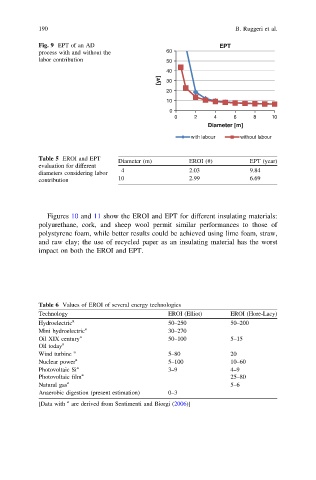

Fig. 9 EPT of an AD EPT

process with and without the 60

labor contribution 50

40

[yr] 30

20

10

0

0 2 4 6 8 10

Diameter [m]

with labour without labour

Table 5 EROI and EPT Diameter (m) EROI (#) EPT (year)

evaluation for different

diameters considering labor 4 2.03 9.84

contribution 10 2.99 6.69

Figures 10 and 11 show the EROI and EPT for different insulating materials:

polyurethane, cork, and sheep wool permit similar performances to those of

polystyrene foam, while better results could be achieved using lime foam, straw,

and raw clay; the use of recycled paper as an insulating material has the worst

impact on both the EROI and EPT.

Table 6 Values of EROI of several energy technologies

Technology EROI (Elliot) EROI (Hore-Lacy)

Hydroelectric a 50–250 50–200

Mini hydroelectric a 30–270

Oil XIX century a 50–100 5–15

Oil today a

Wind turbine a 5–80 20

Nuclear power a 5–100 10–60

Photovoltaic Si a 3–9 4–9

Photovoltaic film a 25–80

Natural gas a 5–6

Anaerobic digestion (present estimation) 0–3

[Data with a are derived from Sentimenti and Biorgi (2006)]