Page 58 - Materials Chemistry, Second Edition

P. 58

44 N. E. Korres

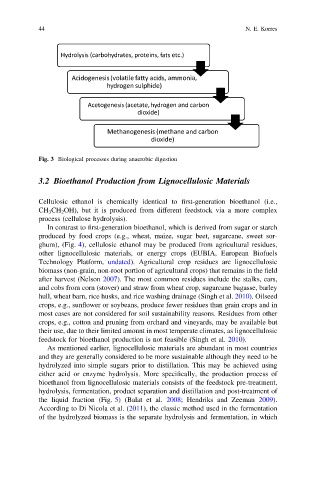

Fig. 3 Biological processes during anaerobic digestion

3.2 Bioethanol Production from Lignocellulosic Materials

Cellulosic ethanol is chemically identical to first-generation bioethanol (i.e.,

CH 3 CH 2 OH), but it is produced from different feedstock via a more complex

process (cellulose hydrolysis).

In contrast to first-generation bioethanol, which is derived from sugar or starch

produced by food crops (e.g., wheat, maize, sugar beet, sugarcane, sweet sor-

ghum), (Fig. 4), cellulosic ethanol may be produced from agricultural residues,

other lignocellulosic materials, or energy crops (EUBIA, European Biofuels

Technology Platform, undated). Agricultural crop residues are lignocellulosic

biomass (non-grain, non-root portion of agricultural crops) that remains in the field

after harvest (Nelson 2007). The most common residues include the stalks, ears,

and cobs from corn (stover) and straw from wheat crop, sugarcane bagasse, barley

hull, wheat barn, rice husks, and rice washing drainage (Singh et al. 2010). Oilseed

crops, e.g., sunflower or soybeans, produce fewer residues than grain crops and in

most cases are not considered for soil sustainability reasons. Residues from other

crops, e.g., cotton and pruning from orchard and vineyards, may be available but

their use, due to their limited amount in most temperate climates, as lignocellulosic

feedstock for bioethanol production is not feasible (Singh et al. 2010).

As mentioned earlier, lignocellulosic materials are abundant in most countries

and they are generally considered to be more sustainable although they need to be

hydrolyzed into simple sugars prior to distillation. This may be achieved using

either acid or enzyme hydrolysis. More specifically, the production process of

bioethanol from lignocellulosic materials consists of the feedstock pre-treatment,

hydrolysis, fermentation, product separation and distillation and post-treatment of

the liquid fraction (Fig. 5) (Balat et al. 2008; Hendriks and Zeeman 2009).

According to Di Nicola et al. (2011), the classic method used in the fermentation

of the hydrolyzed biomass is the separate hydrolysis and fermentation, in which