Page 78 - Materials Chemistry, Second Edition

P. 78

64 N. E. Korres

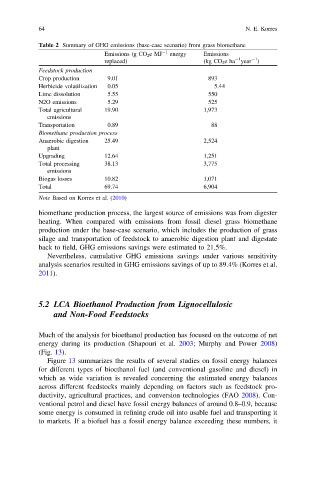

Table 2 Summary of GHG emissions (base-case scenario) from grass biomethane

Emissions (g CO 2 eMJ -1 energy Emissions

-1

-1

replaced) (kg CO 2 eha year )

Feedstock production

Crop production 9.01 893

Herbicide volatilization 0.05 5.44

Lime dissolution 5.55 550

N2O emissions 5.29 525

Total agricultural 19.90 1,973

emissions

Transportation 0.89 88

Biomethane production process

Anaerobic digestion 25.49 2,524

plant

Upgrading 12.64 1,251

Total processing 38.13 3,775

emissions

Biogas losses 10.82 1,071

Total 69.74 6,904

Note Based on Korres et al. (2010)

biomethane production process, the largest source of emissions was from digester

heating. When compared with emissions from fossil diesel grass biomethane

production under the base-case scenario, which includes the production of grass

silage and transportation of feedstock to anaerobic digestion plant and digestate

back to field, GHG emissions savings were estimated to 21.5%.

Nevertheless, cumulative GHG emissions savings under various sensitivity

analysis scenarios resulted in GHG emissions savings of up to 89.4% (Korres et al.

2011).

5.2 LCA Bioethanol Production from Lignocellulosic

and Non-Food Feedstocks

Much of the analysis for bioethanol production has focused on the outcome of net

energy during its production (Shapouri et al. 2003; Murphy and Power 2008)

(Fig. 13).

Figure 13 summarizes the results of several studies on fossil energy balances

for different types of bioethanol fuel (and conventional gasoline and diesel) in

which as wide variation is revealed concerning the estimated energy balances

across different feedstocks mainly depending on factors such as feedstock pro-

ductivity, agricultural practices, and conversion technologies (FAO 2008). Con-

ventional petrol and diesel have fossil energy balances of around 0.8–0.9, because

some energy is consumed in refining crude oil into usable fuel and transporting it

to markets. If a biofuel has a fossil energy balance exceeding these numbers, it