Page 82 - Materials Chemistry, Second Edition

P. 82

4.4 LCSA development in two decades of practice: A case study anthology 77

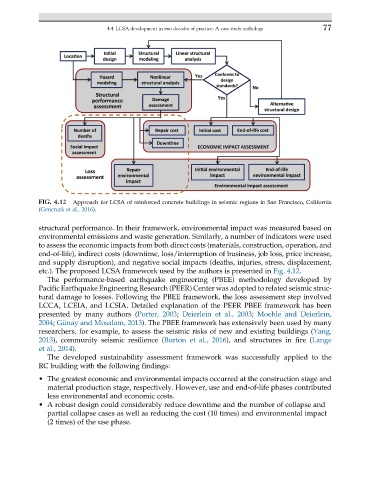

FIG. 4.12 Approach for LCSA of reinforced concrete buildings in seismic regions in San Francisco, California

(Gencturk et al., 2016).

structural performance. In their framework, environmental impact was measured based on

environmental emissions and waste generation. Similarly, a number of indicators were used

to assess the economic impacts from both direct costs (materials, construction, operation, and

end-of-life), indirect costs (downtime, loss/interruption of business, job loss, price increase,

and supply disruption), and negative social impacts (deaths, injuries, stress, displacement,

etc.). The proposed LCSA framework used by the authors is presented in Fig. 4.12.

The performance-based earthquake engineering (PBEE) methodology developed by

Pacific Earthquake Engineering Research (PEER) Center was adopted to related seismic struc-

tural damage to losses. Following the PBEE framework, the loss assessment step involved

LCCA, LCEIA, and LCSIA. Detailed explanation of the PEER PBEE framework has been

presented by many authors (Porter, 2003; Deierlein et al., 2003; Moehle and Deierlein,

2004; G€ unay and Mosalam, 2013). The PBEE framework has extensively been used by many

researchers, for example, to assess the seismic risks of new and existing buildings (Yang,

2013), community seismic resilience (Burton et al., 2016), and structures in fire (Lange

et al., 2014).

The developed sustainability assessment framework was successfully applied to the

RC building with the following findings:

• The greatest economic and environmental impacts occurred at the construction stage and

material production stage, respectively. However, use and end-of-life phases contributed

less environmental and economic costs.

• A robust design could considerably reduce downtime and the number of collapse and

partial collapse cases as well as reducing the cost (10 times) and environmental impact

(2 times) of the use phase.