Page 112 - Lignocellulosic Biomass to Liquid Biofuels

P. 112

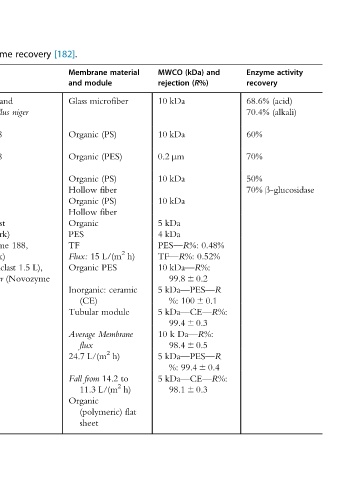

activity (acid) (alkali) β-glucosidase

Enzyme recovery 68.6% 70.4% 60% 70% 50% 70%

and 0.48% 0.52%

(kDa) (R%) kDa—R%: 99.8 6 0.2 kDa—PES—R 100 6 0.1 kDa—CE—R%: 99.4 6 0.3 Da—R%: 98.4 6 0.5 kDa—PES—R 99.4 6 0.4 kDa—CE—R%: 98.1 6 0.3

MWCO rejection kDa 10 kDa 10 μm 0.2 kDa 10 kDa 10 kDa 5 kDa 4 PES—R%: TF—R%: 10 5 %: 5 k 10 5 %: 5

material microfiber (PS) (PES) (PS) fiber (PS) fiber h) L/(m 2 PES ceramic module Membrane h) to 14.2 h) L/(m 2 flat

Membrane module Glass Organic Organic Organic Hollow Organic Hollow Organic 15 Flux: Organic Inorganic: (CE) Tubular Average flux L/(m 2 from 11.3 Organic (polymeric) sheet

[182]. and PES TF 24.7 Fall

recovery niger 188, L), 1.5 (Novozyme

enzyme and reesei Aspergillus 188 188 (Celluclast Denmark) (Novozyme Denmark) (Celluclast niger A. A/S)

assisted Trichoderma from 188) Novozyme A/S) Novozyme A/S) reessei T. reessi T. reesei A/S0, niger A/S, reesei T. from (Novozyme

process cellulase of Type of Cellulase β-glucosidase (Novozyme and Celluclast (Novozymes and Celluclast (Novozymes from Cellulase from Cellulase T. of Cellulase Novozymes A. of Cellobiase Novozymes from Cellulase cellobiase and 188) Celluclast

membrane-based method dilute (1-butyl-3- Mavicell

ultrafiltration Pretreatment and acid Dilute alkali Hydrothermal explosion explosion liquid methylimidazolium chloride) white, and powder,

of Steam Steam Steam Ionic microcrystalline cellulose

Summary cellulose pulp μm (20 BW200 pure pellets CE, cellulose; PES, Polyethersulfone ; PS, polysulfone.

3.2 of straw straw straw straw stalk beet Microcrystalline cellulose powder) Floc delignified, cellulose

Table Source Wheat Wheat Wheat Rice Corn Sugar Solka