Page 117 - Lignocellulosic Biomass to Liquid Biofuels

P. 117

Bioconversion of lignocellulosic biomass to bioethanol and biobutanol 91

Pretreated Hydrolysis

Hydrolyzed

lignocellulosic biomass

biomass

Enzyme

Hydrolysis Separation Solid residue

reactor lignine

Hydrolytic Hexose and

enzymes pentose sugars

Fermentation

Hexose

(glucose)

Separation

fermentation

Hexose reactor Ethanol

fermenting Fermentation

microorganisms

broth rich in

(yeast)

unreacted xylose

Pentose

(xylose) Separation

fermentation

Pentose Ethanol

fermenting reactor

microorganisms

SHF yeast

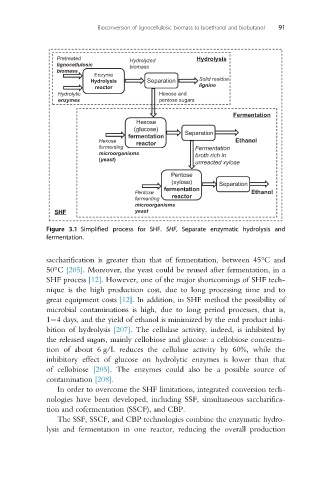

Figure 3.1 Simplified process for SHF. SHF, Separate enzymatic hydrolysis and

fermentation.

saccharification is greater than that of fermentation, between 45°C and

50°C [205]. Moreover, the yeast could be reused after fermentation, in a

SHF process [12]. However, one of the major shortcomings of SHF tech-

nique is the high production cost, due to long processing time and to

great equipment costs [12]. In addition, in SHF method the possibility of

microbial contaminations is high, due to long period processes, that is,

1 4 days, and the yield of ethanol is minimized by the end product inhi-

bition of hydrolysis [207]. The cellulase activity, indeed, is inhibited by

the released sugars, mainly cellobiose and glucose: a cellobiose concentra-

tion of about 6 g/L reduces the cellulase activity by 60%, while the

inhibitory effect of glucose on hydrolytic enzymes is lower than that

of cellobiose [205]. The enzymes could also be a possible source of

contamination [208].

In order to overcome the SHF limitations, integrated conversion tech-

nologies have been developed, including SSF, simultaneous saccharifica-

tion and cofermentation (SSCF), and CBP.

The SSF, SSCF, and CBP technologies combine the enzymatic hydro-

lysis and fermentation in one reactor, reducing the overall production