Page 122 - Lignocellulosic Biomass to Liquid Biofuels

P. 122

96 Lignocellulosic Biomass to Liquid Biofuels

Hemicellulose

hydrolizate

and pretreated Solid residue:

lignocellulosic Direct microbial lignine

biomass conversion (DMC) microorganism biomass

Consolidated

Separation

Bioprocessing

bioreactor Ethanol

with community of

microorganisms

Hexose and

pentose

fermenting

and cellulolytic

producing

microorganism

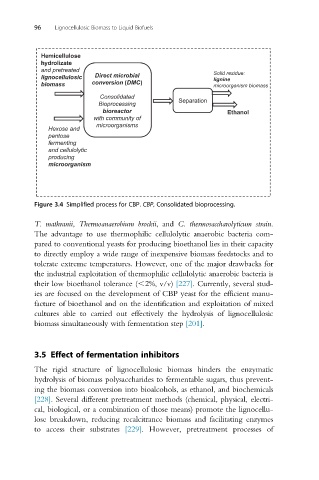

Figure 3.4 Simplified process for CBP. CBP, Consolidated bioprocessing.

T. mathranii, Thermoanaerobium brockii, and C. thermosaccharolyticum strain.

The advantage to use thermophilic cellulolytic anaerobic bacteria com-

pared to conventional yeasts for producing bioethanol lies in their capacity

to directly employ a wide range of inexpensive biomass feedstocks and to

tolerate extreme temperatures. However, one of the major drawbacks for

the industrial exploitation of thermophilic cellulolytic anaerobic bacteria is

their low bioethanol tolerance (,2%, v/v) [227]. Currently, several stud-

ies are focused on the development of CBP yeast for the efficient manu-

facture of bioethanol and on the identification and exploitation of mixed

cultures able to carried out effectively the hydrolysis of lignocellulosic

biomass simultaneously with fermentation step [201].

3.5 Effect of fermentation inhibitors

The rigid structure of lignocellulosic biomass hinders the enzymatic

hydrolysis of biomass polysaccharides to fermentable sugars, thus prevent-

ing the biomass conversion into bioalcohols, as ethanol, and biochemicals

[228]. Several different pretreatment methods (chemical, physical, electri-

cal, biological, or a combination of those means) promote the lignocellu-

lose breakdown, reducing recalcitrance biomass and facilitating enzymes

to access their substrates [229]. However, pretreatment processes of