Page 118 - Lignocellulosic Biomass to Liquid Biofuels

P. 118

92 Lignocellulosic Biomass to Liquid Biofuels

Pretreated

lignocellulosic

biomass Solid residue:

Simultaneous

saccharification lignine

fermentation

Hydrolytic Enzyme hydrolysis Separation

enzymes and Ethanol

hexose

fermentation

Hexose reactor

fermenting Fermentation

microorganisms broth rich in

(yeast) unreacted xylose

Pentose

(xylose) Separation

fermentation

Pentose Ethanol

fermenting reactor

microorganisms

SSF yeast

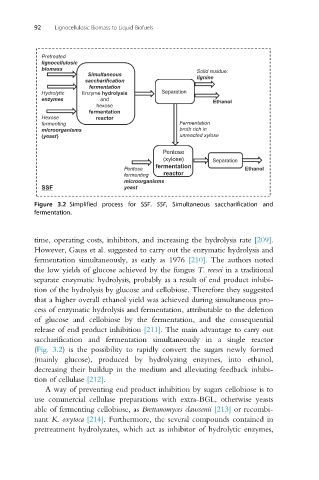

Figure 3.2 Simplified process for SSF. SSF, Simultaneous saccharification and

fermentation.

time, operating costs, inhibitors, and increasing the hydrolysis rate [209].

However, Gauss et al. suggested to carry out the enzymatic hydrolysis and

fermentation simultaneously, as early as 1976 [210]. The authors noted

the low yields of glucose achieved by the fungus T. reesei in a traditional

separate enzymatic hydrolysis, probably as a result of end product inhibi-

tion of the hydrolysis by glucose and cellobiose. Therefore they suggested

that a higher overall ethanol yield was achieved during simultaneous pro-

cess of enzymatic hydrolysis and fermentation, attributable to the deletion

of glucose and cellobiose by the fermentation, and the consequential

release of end product inhibition [211]. The main advantage to carry out

saccharification and fermentation simultaneously in a single reactor

(Fig. 3.2) is the possibility to rapidly convert the sugars newly formed

(mainly glucose), produced by hydrolyzing enzymes, into ethanol,

decreasing their buildup in the medium and alleviating feedback inhibi-

tion of cellulase [212].

A way of preventing end product inhibition by sugars cellobiose is to

use commercial cellulase preparations with extra-BGL, otherwise yeasts

able of fermenting cellobiose, as Brettanomyces claussenii [213] or recombi-

nant K. oxytoca [214]. Furthermore, the several compounds contained in

pretreatment hydrolyzates, which act as inhibitor of hydrolytic enzymes,