Page 238 - Lignocellulosic Biomass to Liquid Biofuels

P. 238

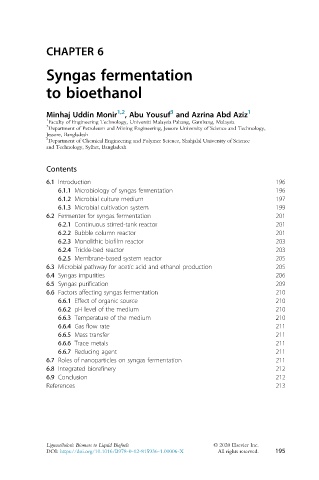

CHAPTER 6

Syngas fermentation

to bioethanol

1,2

3

Minhaj Uddin Monir , Abu Yousuf and Azrina Abd Aziz 1

1

Faculty of Engineering Technology, Universiti Malaysia Pahang, Gambang, Malaysia

2

Department of Petroleum and Mining Engineering, Jessore University of Science and Technology,

Jessore, Bangladesh

3

Department of Chemical Engineering and Polymer Science, Shahjalal University of Science

and Technology, Sylhet, Bangladesh

Contents

6.1 Introduction 196

6.1.1 Microbiology of syngas fermentation 196

6.1.2 Microbial culture medium 197

6.1.3 Microbial cultivation system 199

6.2 Fermenter for syngas fermentation 201

6.2.1 Continuous stirred-tank reactor 201

6.2.2 Bubble column reactor 201

6.2.3 Monolithic biofilm reactor 203

6.2.4 Trickle-bed reactor 203

6.2.5 Membrane-based system reactor 205

6.3 Microbial pathway for acetic acid and ethanol production 205

6.4 Syngas impurities 206

6.5 Syngas purification 209

6.6 Factors affecting syngas fermentation 210

6.6.1 Effect of organic source 210

6.6.2 pH level of the medium 210

6.6.3 Temperature of the medium 210

6.6.4 Gas flow rate 211

6.6.5 Mass transfer 211

6.6.6 Trace metals 211

6.6.7 Reducing agent 211

6.7 Roles of nanoparticles on syngas fermentation 211

6.8 Integrated biorefinery 212

6.9 Conclusion 212

References 213

Lignocellulosic Biomass to Liquid Biofuels © 2020 Elsevier Inc.

DOI: https://doi.org/10.1016/B978-0-12-815936-1.00006-X All rights reserved. 195