Page 54 - Lignocellulosic Biomass to Liquid Biofuels

P. 54

Pretreatment of lignocellulosic biomass for efficient enzymatic saccharification of cellulose 33

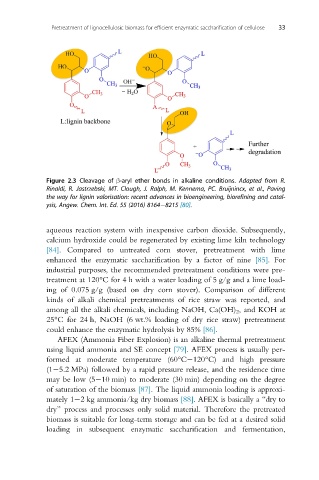

Figure 2.3 Cleavage of β-aryl ether bonds in alkaline conditions. Adapted from R.

Rinaldi, R. Jastrzebski, MT. Clough, J. Ralph, M. Kennema, PC. Bruijnincx, et al., Paving

the way for lignin valorisation: recent advances in bioengineering, biorefining and catal-

ysis, Angew. Chem. Int. Ed. 55 (2016) 8164 8215 [80].

aqueous reaction system with inexpensive carbon dioxide. Subsequently,

calcium hydroxide could be regenerated by existing lime kiln technology

[84]. Compared to untreated corn stover, pretreatment with lime

enhanced the enzymatic saccharification by a factor of nine [85]. For

industrial purposes, the recommended pretreatment conditions were pre-

treatment at 120°C for 4 h with a water loading of 5 g/g and a lime load-

ing of 0.075 g/g (based on dry corn stover). Comparison of different

kinds of alkali chemical pretreatments of rice straw was reported, and

among all the alkali chemicals, including NaOH, Ca(OH) 2 , and KOH at

25°C for 24 h, NaOH (6 wt.% loading of dry rice straw) pretreatment

could enhance the enzymatic hydrolysis by 85% [86].

AFEX (Ammonia Fiber Explosion) is an alkaline thermal pretreatment

using liquid ammonia and SE concept [79]. AFEX process is usually per-

formed at moderate temperature (60°C 120°C) and high pressure

(1 5.2 MPa) followed by a rapid pressure release, and the residence time

may be low (5 10 min) to moderate (30 min) depending on the degree

of saturation of the biomass [87]. The liquid ammonia loading is approxi-

mately 1 2 kg ammonia/kg dry biomass [88]. AFEX is basically a “dry to

dry” process and processes only solid material. Therefore the pretreated

biomass is suitable for long-term storage and can be fed at a desired solid

loading in subsequent enzymatic saccharification and fermentation,