Page 129 - MEMS and Microstructures in Aerospace Applications

P. 129

Osiander / MEMS and microstructures in Aerospace applications DK3181_c006 Final Proof page 118 2.9.2005 9:38am

118 MEMS and Microstructures in Aerospace Applications

Unbiased-

OFF

A A'

Biased-

ON

(cross section through A-A')

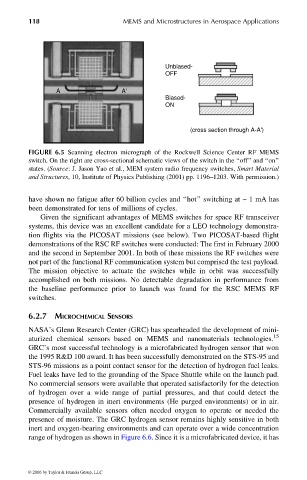

FIGURE 6.5 Scanning electron micrograph of the Rockwell Science Center RF MEMS

switch. On the right are cross-sectional schematic views of the switch in the ‘‘off’’ and ‘‘on’’

states. (Source: J. Jason Yao et al., MEM system radio frequency switches, Smart Material

and Structures, 10, Institute of Physics Publishing (2001) pp. 1196–1203. With permission.)

have shown no fatigue after 60 billion cycles and ‘‘hot’’ switching at ~ 1 mA has

been demonstrated for tens of millions of cycles.

Given the significant advantages of MEMS switches for space RF transceiver

systems, this device was an excellent candidate for a LEO technology demonstra-

tion flights via the PICOSAT missions (see below). Two PICOSAT-based flight

demonstrations of the RSC RF switches were conducted: The first in February 2000

and the second in September 2001. In both of these missions the RF switches were

not part of the functional RF communication system but comprised the test payload.

The mission objective to actuate the switches while in orbit was successfully

accomplished on both missions. No detectable degradation in performance from

the baseline performance prior to launch was found for the RSC MEMS RF

switches.

6.2.7 MICROCHEMICAL SENSORS

NASA’s Glenn Research Center (GRC) has spearheaded the development of mini-

aturized chemical sensors based on MEMS and nanomaterials technologies. 15

GRC’s most successful technology is a microfabricated hydrogen sensor that won

the 1995 R&D 100 award. It has been successfully demonstrated on the STS-95 and

STS-96 missions as a point contact sensor for the detection of hydrogen fuel leaks.

Fuel leaks have led to the grounding of the Space Shuttle while on the launch pad.

No commercial sensors were available that operated satisfactorily for the detection

of hydrogen over a wide range of partial pressures, and that could detect the

presence of hydrogen in inert environments (He purged environments) or in air.

Commercially available sensors often needed oxygen to operate or needed the

presence of moisture. The GRC hydrogen sensor remains highly sensitive in both

inert and oxygen-bearing environments and can operate over a wide concentration

range of hydrogen as shown in Figure 6.6. Since it is a microfabricated device, it has

© 2006 by Taylor & Francis Group, LLC