Page 243 - MEMS and Microstructures in Aerospace Applications

P. 243

Osiander / MEMS and microstructures in Aerospace applications DK3181_c011 Final Proof page 234 1.9.2005 12:31pm

234 MEMS and Microstructures in Aerospace Applications

11.2.1 PULSED PLASMA THRUSTER

Conventionally scaled pulsed plasma thrusters have been used in the past success-

fully and are fully space qualified. 9–16 Thrust is produced by ablating and acceler-

ating a solid insulator, such as Teflon, using a surface discharge initiated by high

voltage. Usually these systems are fairly massive ( 5 kg), but recent efforts have

been made to shrink the PPT for the use in micro- and nano-spacecraft. A micro-

pulsed plasma thruster (mPPT) has been developed by AFRL and Busek using

coaxial thruster configurations. A power conversion system converts the bus volt-

age to approximately 1 kV levels to ignite the discharge. Specific impulse (I sp )

values can reach up to 1000 sec, with mN-sec impulse bits.

11.2.1.1 Principle of Operation

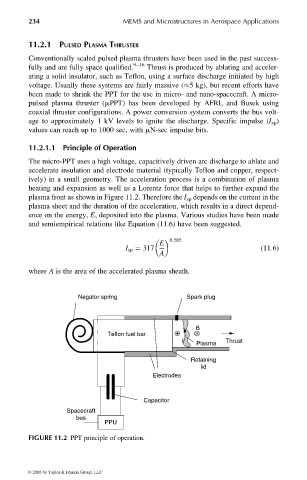

The micro-PPT uses a high voltage, capacitively driven arc discharge to ablate and

accelerate insulation and electrode material (typically Teflon and copper, respect-

ively) in a small geometry. The acceleration process is a combination of plasma

heating and expansion as well as a Lorentz force that helps to further expand the

plasma front as shown in Figure 11.2. Therefore the I sp depends on the current in the

plasma sheet and the duration of the acceleration, which results in a direct depend-

ence on the energy, E, deposited into the plasma. Various studies have been made

and semiempirical relations like Equation (11.6) have been suggested.

0:585

E

I sp ¼ 317 (11:6)

A

where A is the area of the accelerated plasma sheath.

Negator spring Spark plug

B

Teflon fuel bar

i Thrust

Plasma

Retaining

lid

Electrodes

Capacitor

Spacecraft

bus

PPU

FIGURE 11.2 PPT principle of operation.

© 2006 by Taylor & Francis Group, LLC