Page 57 - Machine Learning for Subsurface Characterization

P. 57

Characterization of fracture-induced geomechanical alterations Chapter 2 43

Receiver Transmitter

transducers transducers

Receiver

1 1 Direction of transducers Sample Transmitter

transducer cut off transducers Sample

2 2 polarization 1 cut off

1

3 3

2

2

4

6 in. 4 3

3

Direction of

5 5 4 transducer

4 polarization

6 in.

Scanning 5 direction 5

6 6 Scanning

direction

direction

direction

7 7 Scanning 6 6 Scanning

7

7

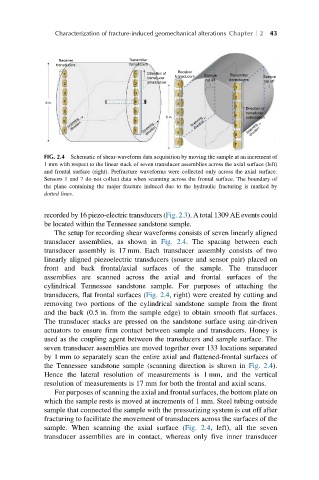

FIG. 2.4 Schematic of shear-waveform data acquisition by moving the sample at an increment of

1 mm with respect to the linear stack of seven transducer assemblies across the axial surface (left)

and frontal surface (right). Prefracture waveforms were collected only across the axial surface.

Sensors 1 and 7 do not collect data when scanning across the frontal surface. The boundary of

the plane containing the major fracture induced due to the hydraulic fracturing is marked by

dotted lines.

recorded by 16 piezo-electric transducers (Fig. 2.3). A total 1309 AE events could

be located within the Tennessee sandstone sample.

The setup for recording shear waveforms consists of seven linearly aligned

transducer assemblies, as shown in Fig. 2.4. The spacing between each

transducer assembly is 17 mm. Each transducer assembly consists of two

linearly aligned piezoelectric transducers (source and sensor pair) placed on

front and back frontal/axial surfaces of the sample. The transducer

assemblies are scanned across the axial and frontal surfaces of the

cylindrical Tennessee sandstone sample. For purposes of attaching the

transducers, flat frontal surfaces (Fig. 2.4, right) were created by cutting and

removing two portions of the cylindrical sandstone sample from the front

and the back (0.5 in. from the sample edge) to obtain smooth flat surfaces.

The transducer stacks are pressed on the sandstone surface using air-driven

actuators to ensure firm contact between sample and transducers. Honey is

used as the coupling agent between the transducers and sample surface. The

seven transducer assemblies are moved together over 133 locations separated

by 1 mm to separately scan the entire axial and flattened-frontal surfaces of

the Tennessee sandstone sample (scanning direction is shown in Fig. 2.4).

Hence the lateral resolution of measurements is 1 mm, and the vertical

resolution of measurements is 17 mm for both the frontal and axial scans.

For purposes of scanning the axial and frontal surfaces, the bottom plate on

which the sample rests is moved at increments of 1 mm. Steel tubing outside

sample that connected the sample with the pressurizing system is cut off after

fracturing to facilitate the movement of transducers across the surfaces of the

sample. When scanning the axial surface (Fig. 2.4, left), all the seven

transducer assemblies are in contact, whereas only five inner transducer