Page 192 - Machinery Component Maintenance

P. 192

174 Machinery Component Maintenance and Repair

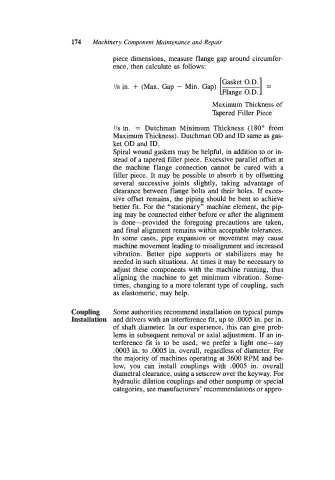

piece dimensions, measure flange gap around circumfer-

ence, then calculate as follows:

I Flange O.D. I=

Gasket 0. D .

l/8 in. + (Max. Gap - Min. Gap)

Maximum Thickness of

Tapered Filler Piece

1/8 in. = Dutchman Minimum Thickness (180’ from

Maximum Thickness). Dutchman OD and ID same as gas-

ket OD and ID.

Spiral wound gaskets may be helpful, in addition to or in-

stead of a tapered filler piece. Excessive parallel offset at

the machine flange connection cannot be cured with a

filler piece. It may be possible to absorb it by offsetting

several successive joints slightly, taking advantage of

clearance between flange bolts and their holes. If exces-

sive offset remains, the piping should be bent to achieve

better fit. For the “stationary” machine element, the pip-

ing may be connected either before or after the alignment

is done-provided the foregoing precautions are taken,

and final alignment remains within acceptable tolerances.

In some cases, pipe expansion or movement may cause

machine movement leading to misalignment and increased

vibration. Better pipe supports or stabilizers may be

needed in such situations. At times it may be necessary to

adjust these components with the machine running, thus

aligning the machine to get minimum vibration. Some-

times, changing to a more tolerant type of coupling, such

as elastomeric, may help.

Coupling Some authorities recommend installation on typical pumps

Installation and drivers with an interference fit, up to .OW5 in. per in.

of shaft diameter. In our experience, this can give prob-

lems in subsequent removal or axial adjustment. If an in-

terference fit is to be used, we prefer a light one-say

.OOO3 in. to .OOO5 in. overall, regardless of diameter. For

the majority of machines operating at 3600 RPM and be-

low, you can install couplings with .0005 in. overall

diametral clearance, using a setscrew over the keyway. For

hydraulic dilation couplings and other nonpump or special

categories, see manufacturers’ recommendations or appro-