Page 214 - Machinery Component Maintenance

P. 214

1% Machinery Component Maintenance and Repair

1

Amount of I IF--. _._I ____ a .# __ I

Shim Removal IFp2?-

~

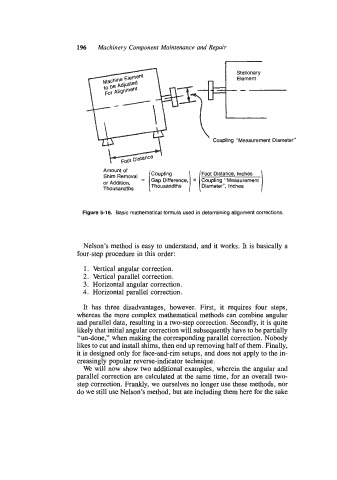

Figure 5-16. Basic mathematical formula used in determining alignment corrections.

Nelson’s method is easy to understand, and it works. It is basically a

four-step procedure in this order:

1. Vertical angular Correction.

2. Vertical parallel correction.

3. Horizontal angular correction.

4. Horizontal parallel correction.

It has three disadvantages, however. First, it requires four steps,

whereas the more complex mathematical methods can combine angular

and parallel data, resulting in a two-step correction. Secondly, it is quite

likely that initial angular correction will subsequently have to be partially

“un-done,” when making the corresponding parallel correction. Nobody

likes to cut and install shims, then end up removing half of them. Finally,

it is designed only for face-and-rim setups, and does not apply to the in-

creasingly popular reverse-indicator technique.

We will now show two additional examples, wherein the angular and

parallel correction are calculated at the same time, for an overall two-

step correction. Frankly, we ourselves no longer use these methods, nor

do we still use Nelson’s method, but are including them here for the sake