Page 273 - Machinery Component Maintenance

P. 273

Balancing of Machinery Components 255

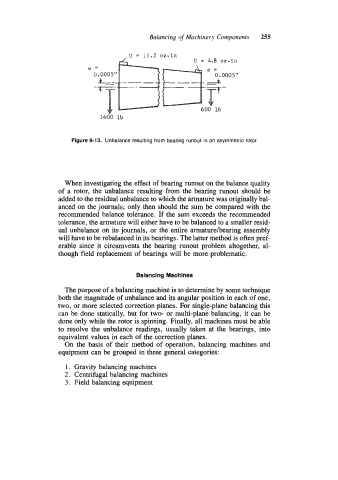

Figure 6-13. Unbalance resulting from bearing runout in an asymmetric rotor.

When investigating the effect of bearing runout on the balance quality

of a rotor, the unbalance resulting from the bearing runout should be

added to the residual unbalance to which the armature was originally bal-

anced on the journals; only then should the sum be compared with the

recommended balance tolerance. If the sum exceeds the recommended

tolerance, the armature will either have to be balanced to a smaller resid-

ual unbalance on its journals, or the entire armature/bearing assembly

will have to be rebalanced in its bearings. The latter method is often pref-

erable since it circumvents the bearing runout problem altogether, al-

though field replacement of bearings will be more problematic.

Balancing Machines

The purpose of a balancing machine is to determine by some technique

both the magnitude of unbalance and its angular position in each of one,

two, or more selected correction planes. For single-plane balancing this

can be done statically, but for two- or multi-plane balancing, it can be

done only while the rotor is spinning. Finally, all machines must be able

to resolve the unbalance readings, usually taken at the bearings, into

equivalent values in each of the correction planes.

On the basis of their method of operation, balancing machines and

equipment can be grouped in three general categories:

I. Gravity balancing machines

2. Centrifugal balancing machines

3. Field balancing equipment