Page 274 - Machinery Component Maintenance

P. 274

256 Machinery Component Maintenance and Repair

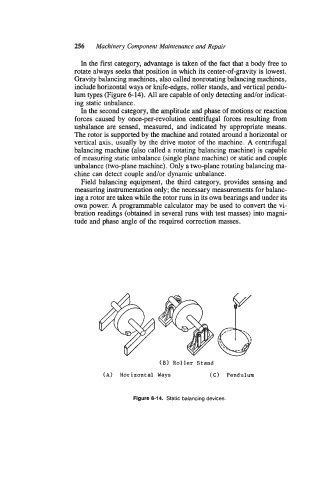

In the first category, advantage is taken of the fact that a body free to

rotate always seeks that position in which its center-of-gravity is lowest.

Gravity balancing machines, also called nonrotating balancing machines,

include horizontal ways or knife-edges, roller stands, and vertical pendu-

lum types (Figure 6-14). All are capable of only detecting and/or indicat-

ing static unbalance.

In the second category, the amplitude and phase of motions or reaction

forces caused by once-per-revolution centrifugal forces resulting from

unbalance are sensed, measured, and indicated by appropriate means.

The rotor is supported by the machine and rotated around a horizontal or

vertical axis, usually by the drive motor of the machine. A centrifugal

balancing machine (also called a rotating balancing machine) is capable

of measuring static unbalance (singlc planc machinc) or static and couple

unbalance (two-plane machine). Only a two-plane rotating balancing ma-

chine can detect couple and/or dynamic unbalance.

Field balancing equipment, the third category, provides sensing and

measuring instrumentation only; the necessary measurements for balanc-

ing a rotor are taken while the rotor runs in its own bearings and under its

own power. A programmable calculator may be used to convert the vi-

bration readings (obtained in several runs with test masses) into magni-

tude and phase angle of the required correction masses.

(B) Roller Stand

(A) Horizontal Ways (C) Pendulum

Figure 6-14. Static balancing devices.