Page 304 - Machinery Component Maintenance

P. 304

286 Machinery Component Maintenance and Repair

To eliminate the need for physically biasing an arbor, balancing ma-

chine instrumentation can be furnished with a "double compensator."

This feature permits biasing of the machine indication by means of suit-

able electrical circuits.

The Double Compensator

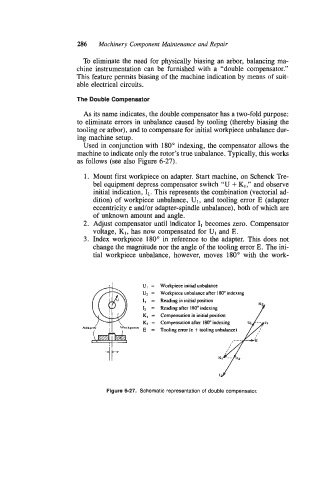

As its name indicates, the double compensator has a two-fold purpose:

to eliminate errors in unbalance caused by tooling (thereby biasing the

tooling or arbor), and to compensate for initial workpiece unbalance dur-

ing machine setup.

Used in conjunction with 180" indexing, the compensator allows the

machine to indicate only the rotor's true unbalance. Typically, this works

as follows (see also Figure 6-27).

1. Mount first workpiece on adapter. Start machine, on Schenck Tre-

bel equipment depress compensator switch "U + K1 ," and observe

initial indication, I1. This represents the combination (vectorial ad-

dition) of workpiece unbalance, U1, and tooling error E (adapter

eccentricity e and/or adapter-spindle unbalance) , both of which are

of unknown amount and angle.

2. Adjust compensator until indicator 1, becomes zero. Compensator

voltage, K1, has now compensated for U1 and E.

3. Index workpiece 180" in reference to the adapter. This does not

change the magnitude nor the angle of the tooling error E. The ini-

tial workpiece unbalance, however, moves 180" with the work-

I

U, = Workpiece initial unbalance

U2 = Workpiece unbalance after 180" indexing

II = Reading in initial position

K2

after

Reading

p

in

=

l2 K, = Compensation 180" initial indexing i t i o j

K2 = Compensation after 180" indexing UI -- I,

Ada kpirce

E = Tooling error (e + tooling unbalance)

KI -- 118

Ia

Figure 6-27. Schematic representation of double compensator.