Page 65 - Macromolecular Crystallography

P. 65

54 MACROMOLECULAR CRYS TALLOGRAPHY

3.6 Control of the evaporation kinetics

(a) of vapour diffusion trials

Thin layer of

paraffin oil The formation of numerous, small crystals instead

of the desired large single ones can occur due to

the crystallization process taking place too rapidly.

A means to slow down the equilibration rate in

vapour diffusion and thereby approach supersatu-

Crystallization ration more slowly in order to avoid the formation

drop

of ‘showers’, twinned crystals, or precipitate, is

by placing a mixture of paraffin and silicone oils

as a barrier over the reservoirs of hanging or sit-

ting drop trials (Chayen, 1997b). Paraffin oil totally

blocks all vapour diffusion, resulting in drying out

(b) of the drops, while silicon oil allows diffusion to

take place fully. The equilibration rate is therefore

Dispenser

dictated by the ratio of the two oils and by the

thickness of the oil–mixture layer (Protocol 3.8).

Thick layer of

paraffin oil Equal volumes of paraffin and silicon, in a layer

of 250–500 µl, placed over 0.6–1 ml reservoirs in

Linbro type plates were found to be optimal. This

method has been successful in crystallizing prob-

lematic target proteins (e.g. Mandelman et al., 2002;

Isupov et al., 2004). The advantage of this technique

is that no change is required to the crystallization

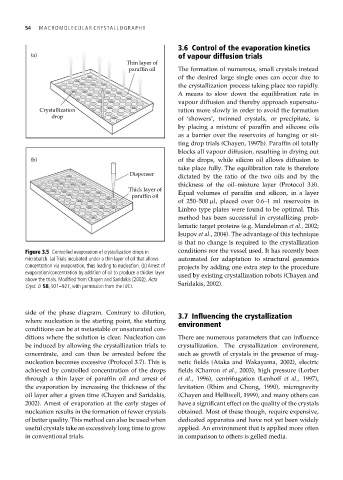

Figure 3.5 Controlled evaporation of crystallization drops in conditions nor the vessel used. It has recently been

microbatch. (a) Trials incubated under a thin layer of oil that allows automated for adaptation to structural genomics

concentration via evaporation, thus leading to nucleation. (b) Arrest of projects by adding one extra step to the procedure

evaporation/concentration by addition of oil to produce a thicker layer used by existing crystallization robots (Chayen and

above the trials. Modified from Chayen and Saridakis (2002), Acta

Cryst. D 58, 921–927, with permission from the IUCr. Saridakis, 2002).

side of the phase diagram. Contrary to dilution, 3.7 Influencing the crystallization

where nucleation is the starting point, the starting environment

conditions can be at metastable or unsaturated con-

ditions where the solution is clear. Nucleation can There are numerous parameters that can influence

be induced by allowing the crystallization trials to crystallization. The crystallization environment,

concentrate, and can then be arrested before the such as growth of crystals in the presence of mag-

nucleation becomes excessive (Protocol 3.7). This is netic fields (Ataka and Wakayama, 2002), electric

achieved by controlled concentration of the drops fields (Charron et al., 2003), high pressure (Lorber

through a thin layer of paraffin oil and arrest of et al., 1996), centrifugation (Lenhoff et al., 1997),

the evaporation by increasing the thickness of the levitation (Rhim and Chung, 1990), microgravity

oil layer after a given time (Chayen and Saridakis, (Chayen and Helliwell, 1999), and many others can

2002). Arrest of evaporation at the early stages of have a significant effect on the quality of the crystals

nucleation results in the formation of fewer crystals obtained. Most of these though, require expensive,

of better quality. This method can also be used when dedicated apparatus and have not yet been widely

useful crystals take an excessively long time to grow applied. An environment that is applied more often

in conventional trials. in comparison to others is gelled media.