Page 249 - Making things move_ DIY mechanisms for inventors, hobbyists, and artists

P. 249

Chapter 7 Bearings, Couplers, Gears, Screws, and Springs 227

Pulleys and Sprockets, Belts and Chains

Belt or chain drives are often preferred over gears when torque needs to be

transferred over long distances. Imagine how funny a bicycle would look with a bunch

of gears between the pedals and the back wheel. They are also more forgiving about

misalignment than gear systems are.

Sprockets, like the ones on your bicycle, are used with chains. Pulleys are used with

belts, and can be flat or V-shaped with matching belts or grooved pulleys with

matching toothed belts. We covered the latter type, called a timing belt pulley system,

in Chapter 1. The pulleys and sprockets that come with hubs and set screws are

mounted on shafts and motors to do the work. Remember that you have a mechanical

advantage only if the input pulley is smaller than the output pulley, and the advantage

is just the ratio of their sizes. For example, if your input pulley is half the diameter of

the output, your mechanical advantage is 2:1.

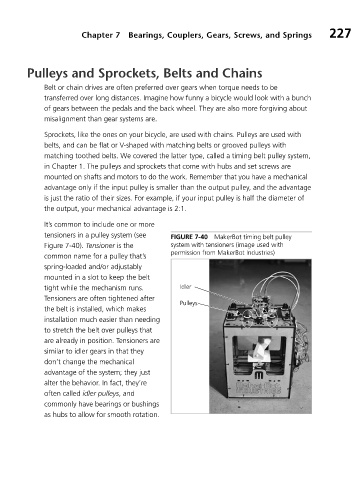

It’s common to include one or more

tensioners in a pulley system (see FIGURE 7-40 MakerBot timing belt pulley

Figure 7-40). Tensioner is the system with tensioners (image used with

permission from MakerBot Industries)

common name for a pulley that’s

spring-loaded and/or adjustably

mounted in a slot to keep the belt

tight while the mechanism runs. Idler

Tensioners are often tightened after

Pulleys

the belt is installed, which makes

installation much easier than needing

to stretch the belt over pulleys that

are already in position. Tensioners are

similar to idler gears in that they

don’t change the mechanical

advantage of the system; they just

alter the behavior. In fact, they’re

often called idler pulleys, and

commonly have bearings or bushings

as hubs to allow for smooth rotation.