Page 56 - Making things move_ DIY mechanisms for inventors, hobbyists, and artists

P. 56

Chapter 2 Materials: How to Choose and Where to Find Them 37

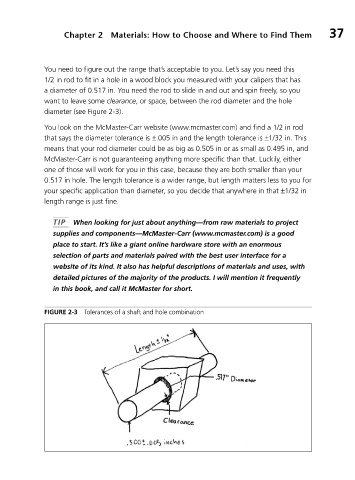

You need to figure out the range that’s acceptable to you. Let’s say you need this

1/2 in rod to fit in a hole in a wood block you measured with your calipers that has

a diameter of 0.517 in. You need the rod to slide in and out and spin freely, so you

want to leave some clearance, or space, between the rod diameter and the hole

diameter (see Figure 2-3).

You look on the McMaster-Carr website (www.mcmaster.com) and find a 1/2 in rod

that says the diameter tolerance is ±.005 in and the length tolerance is ±1/32 in. This

means that your rod diameter could be as big as 0.505 in or as small as 0.495 in, and

McMaster-Carr is not guaranteeing anything more specific than that. Luckily, either

one of those will work for you in this case, because they are both smaller than your

0.517 in hole. The length tolerance is a wider range, but length matters less to you for

your specific application than diameter, so you decide that anywhere in that ±1/32 in

length range is just fine.

TIP When looking for just about anything—from raw materials to project

supplies and components—McMaster-Carr (www.mcmaster.com) is a good

place to start. It’s like a giant online hardware store with an enormous

selection of parts and materials paired with the best user interface for a

website of its kind. It also has helpful descriptions of materials and uses, with

detailed pictures of the majority of the products. I will mention it frequently

in this book, and call it McMaster for short.

FIGURE 2-3 Tolerances of a shaft and hole combination