Page 110 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 110

Section 3.2 Density 89

examples ofthe importance of physical properties are discussed in this chapter, with

each property being presented from the viewpoint of material selection and manu-

facturing and its relevance to the service life of the component.

3.2 Density

The density of a material is its mass per unit volume. Another term is specific

gravity, which expresses a material’s density in relation to that of Water; thus, speci-

fic gravity has no units. The range of densities for a variety of materials at room

temperature, along with other properties, is given in Tables 3.1 and 3.2.

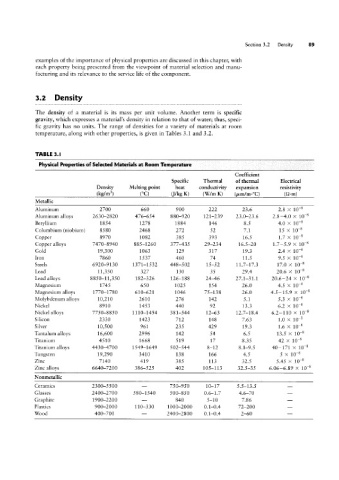

TABLE 3.l

Physical Properties of Selected Materials at Room Temperature

Coefficient

Specific Thermal of thermal Electrical

Density Melting point heat conductivity expansion resistivity

(kg/m3) (°C) (J/kg K) (W/m K) (pm/m-°C) (Q-m)

Metallic

Aluminum 2700 660 900 222 23.6 2.8 >< 1078

Aluminum alloys 2630-2820 476-654 880-920 121-239 23.0-23.6 2.8-4.0 >< 1078

Beryllium 1854 1278 1884 146 8.5 4.0 >< 1078

Columbium (niobium) 8580 2468 272 52 7.1 15 >< 1078

Copper 8970 1082 385 393 16.5 1.7 >< 1078

Copper alloys 7470-8940 885-1260 377-435 29-234 16.5-20 1.7-5.9 >< 1078

Gold 19,300 1063 129 317 19.3 2.4 >< 1078

Iron 7860 1537 460 74 11.5 9.5 >< 1078

Steels 6920-9130 1371-1532 448-502 15-52 11.7-17.3 17.0 >< 1078

Lead 11,350 327 130 35 29.4 20.6 >< 1078

Lead alloys 8850-11,350 182-326 126-188 24-46 27.1-31.1 20.6-24 >< 1078

Magnesium 1745 650 1025 154 26.0 4.5 >< 1078

Magnesium alloys 1770-1780 610-621 1046 75-138 26.0 4.5-15.9 >< 1078

Molybdenum alloys 10,210 2610 276 142 5.1 5.3 >< 1078

Nickel 8910 1453 440 92 13.3 6.2 >< 1078

Nickel alloys 7750-8850 1110-1454 381-544 12-63 12.7-18.4 6.2-110 >< 1078

Silicon 2330 1423 712 148 7.63 1.0 >< 1073

Silver 10,500 961 235 429 19.3 1.6 >< 1078

Tantalum alloys 16,600 2996 142 54 6.5 13.5 >< 1078

Titanium 4510 1668 519 17 8.35 42 >< 1078

Titanium alloys 4430-4700 1549-1649 502-544 8-12 8.1-9.5 40~171 >< 1078

Tungsten 19,290 3410 138 166 4.5 5 >< 1078

Zinc 7140 419 385 113 32.5 5.45 >< 1078

Zinc alloys 6640-7200 386-525 402 105-113 32.5-35 6.06-6.89 >< 1078

Nonmetallic

Ceramics 2300-5500 - 750-950 10-17 5.5-13.5 -

-

-

Glasses 2400-2700 580-1540 500-850 0.6-1.7 4.6-70 -

Graphite 1900-2200 840 5-10 7.86 -

Plastics 900-2000 110-330 1000-2000 0.1-0.4 72-200

Wood 400-700 - 2400-2800 0.1-0.4 2-60 -