Page 314 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 314

Synthesis, Design, and Projects 293

volume of each riser is the same and the height of each is equal

to the diameter. (See Example 1O.1.)

I I.48. Sketch and describe a casting line consisting of ma-

chinery, conveyors, robots, sensors, etc., that automatically

could perform the expendable-pattern casting process.

II.49. Outline the casting processes that would be most

suitable for making small toys. Explain your choices.

I I.50. Make a list ofthe mold and die materials used in the

casting processes described in this chapter. Under each type of

material, list the casting processes that are employed and Dimensions in mm

explain Why these processes are suitable for that particular

mold or die material.

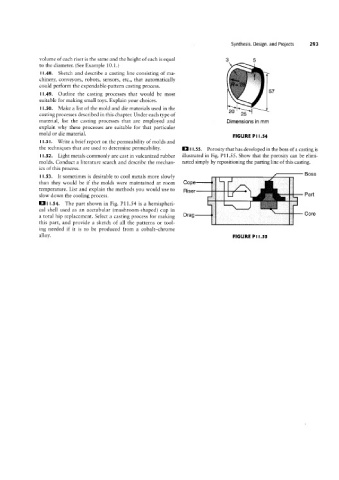

FIGURE PI l.54

I I.5 I. Write a brief report on the permeability of molds and

the techniques that are used to determine permeability.

II I I.55. Porosity that has developed in the boss ofa casting is

I I.52. Light metals commonly are cast in vulcanized rubber illustrated in Fig. 1311.55 Show that the porosity can be elimi-

molds. Conduct a literature Search and describe the mechan- nated simply by repositioning the parting line of this casting.

ics of this process.

Boss

I l.53. It sometimes is desirable to cool metals more slowly

than they would be if the molds were maintained at room

temperature. List and explain the methods you would use to Riser Part

slow down the cooling process.

III I.54. The part shown in Fig. P1].54 is a hemispheri-

cal shell used as an acetabular (mushroom-shaped) cup in

a total hip replacement. Select a casting process for making Core

this part, and provide a sketch of all the patterns or tool-

ing needed if it is to be produced from a cobalt-chrome

alloy. FIGURE PI l.55