Page 141 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 141

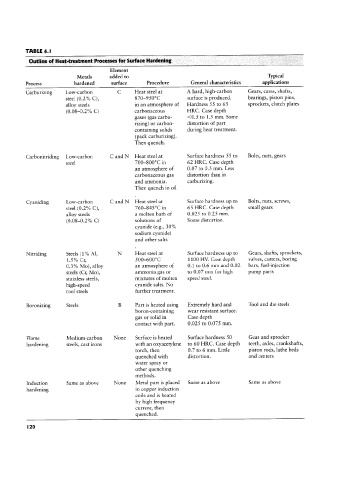

TABLE 4.l

Outline of Heat-treatment Processes for Surface Hardening

Element

Metals added to Typical

Process hardened surface Procedure General characteristics applications

Carburizing Low-carbon C Heat steel at A hard, high-carbon Gears, cams, shafts,

steel (0.2% C), 870-950°C surface is produced. bearings, piston pins,

alloy steels in an atmosphere of Hardness 55 to 65 sprockets, clutch plates

(0.08-0.2% C) carbonaceous HRC. Case depth

gases (gas carbu- <0.5 to 1.5 mm. Some

rizing) or carbon- distortion of part

containing solids during heat treatment.

(pack carburizing).

Then quench.

Carbonitriding Low-carbon C and N Heat steel at Surface hardness 55 to Bolts, nuts, gears

steel 700-800°C in 62 HRC. Case depth

an atmosphere of 0.07 to 0.5 mm. Less

carbonaceous gas distortion than in

and ammonia. carburizing.

Then quench in oil

Cyaniding Low-carbon C and N Heat steel at Surface hardness up to Bolts, nuts, screws,

steel (0.2% C), 760-845°C in 65 HRC. Case depth small gears

alloy steels a molten bath of 0.025 to 0.25 mm.

(0.08-0.2% C) solutions of Some distortion.

cyanide (e.g., 30%

sodium cyanide)

and other salts

Nitriding Steels (1% Al, N Heat steel at Surface hardness up to Gears, shafts, sprockets,

1.5% Cr, 500-600°C 1100 HV. Case depth valves, cutters, boring

0.3% Mo), alloy an atmosphere of 0.1 to 0.6 mm and 0.02 bars, fuel-injection

steels (Cr, Mo), ammonia gas or to 0.07 mm for high pump parts

stainless steels, mixtures of molten speed steel.

high-speed cyanide salts. No

tool steels further treatment.

Boronizing Steels B Part is heated using Extremely hard and Tool and die steels

boron-containing Wear resistant surface.

gas or solid in Case depth

contact with part. 0.025 to 0.075 mm.

Flame Medium-carbon None Surface is heated Surface hardness 50 Gear and sprocket

hardening steels, cast irons with an oxyacetylene to 60 HRC. Case depth teeth, axles, crankshafts

torch, then 0.7 to 6 mm. Little piston rods, lathe beds

quenched with distortion. and centers

Water spray or

other quenching

methods.

Induction Same as above None Metal part is placed Same as above Same as above

hardening in copper induction

coils and is heated

by high frequency

current, then

quenched.

|20