Page 146 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 146

Section 4.13 Design Considerations for Heat Treating

Induction

Cooling coils /

water Shaqed

`|T'ave|

Slideway to

be surface

Part to hardened

be heated

and quenched

(H) (D) (C)

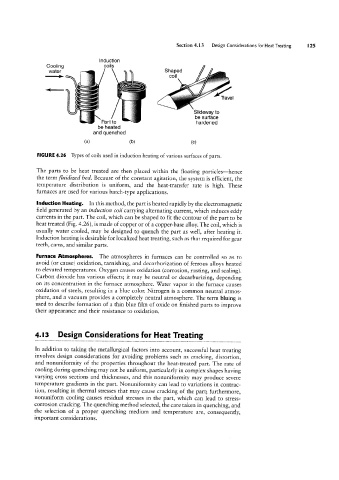

FIGURE 4.26 Types of coils used in induction heating of various surfaces of parts.

The parts to be heat treated are then placed Within the floating particles-hence

the term fiuidizea' bed. Because of the constant agitation, the system is efficient, the

temperature distribution is uniform, and the heat-transfer rate is high. These

furnaces are used for various batch-type applications.

Induction Heating. In this method, the part is heated rapidly by the electromagnetic

field generated by an induction coil carrying alternating current, which induces eddy

currents in the part. The coil, which can be shaped to fit the contour of the part to be

heat treated (Fig. 426), is made of copper or of a copper-base alloy. The coil, which is

usually Water cooled, may be designed to quench the part as Well, after heating it.

Induction heating is desirable for localized heat treating, such as that required for gear

teeth, cams, and similar parts.

Furnace Atmospheres. The atmospheres in furnaces can be controlled so as to

avoid (or cause) oxidation, tarnishing, and decarburization of ferrous alloys heated

to elevated temperatures. Oxygen causes oxidation (corrosion, rusting, and scaling).

Carbon dioxide has various effects; it may be neutral or decarburizing, depending

on its concentration in the furnace atmosphere. Water vapor in the furnace causes

oxidation of steels, resulting in a blue color. Nitrogen is a common neutral atmos-

phere, and a vacuum provides a completely neutral atmosphere. The term bluing is

used to describe formation of a thin blue film of oxide on finished parts to improve

their appearance and their resistance to oxidation.

4.l3 Design Considerations for Heat Treating

In addition to taking the metallurgical factors into account, successful heat treating

involves design considerations for avoiding problems such as cracking, distortion,

and nonuniformity of the properties throughout the heat-treated part. The rate of

cooling during quenching may not be uniform, particularly in complex shapes having

varying cross sections and thicknesses, and this nonuniformity may produce severe

temperature gradients in the part. Nonuniformity can lead to variations in contrac-

tion, resulting in thermal stresses that may cause cracking of the part; furthermore,

nonuniform cooling causes residual stresses in the part, which can lead to stress-

corrosion cracking. The quenching method selected, the care taken in quenching, and

the selection of a proper quenching medium and temperature are, consequently,

important considerations.