Page 250 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 250

Section 9.6 Ceramic matrix Composites 22

TABLE 9.4

Summary of Fiber and Material Properties for an

Automotive Brake Caliper

Aluminum-reinforced

Property Alumina fiber composite material

Tensile strength 3100 MPa 1.5 GPa

Elastic modulus 380 GPa 270 GPa

Density 3.9 g/cm3 3.48 g/cm3

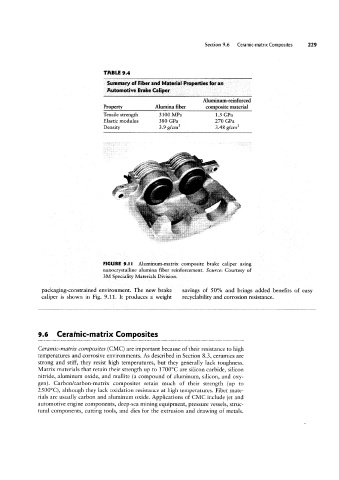

FIGURE 9.I| Aluminum-matrix composite brake caliper using

nanocrystalline alumina fiber reinforcement. Source: Courtesy of

3M Speciality Materials Division.

packaging-constrained environment. The new brake savings of 50% and brings added benefits of easy

caliper is shown in Fig. 9.11. It produces a weight recyclability and corrosion resistance

9.6 Ceramic-matrix Composites

Ceramic-matrix composites (CMC) are important because of their resistance to high

temperatures and corrosive environments. As described in Section 8.3, ceramics are

strong and stiff, they resist high temperatures, but they generally lack toughness.

Matrix materials that retain their strength up to 1700°C are silicon carbide, silicon

nitride, aluminum oxide, and mullite (a compound of aluminum, silicon, and oxy-

gen). Carbon/carbon-matrix composites retain much of their strength (up to

2500°C), although they lack oxidation resistance at high temperatures. Fiber mate-

rials are usually carbon and aluminum oxide. Applications of CMC include jet and

automotive engine components, deep-sea mining equipment, pressure vessels, struc-

tural components, cutting tools, and dies for the extrusion and drawing of metals.