Page 247 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 247

Chapter 9 Composite Materials: Structure, General Properties, and Applications

Double coating of polyurethane

Extra tough three-layer

7

multiaxial glass weave

A ,

i`i'

A

lacquer with nonskid finish

Impact and ultraviolet-resistant

Stringer \ ~,e ~

~ - .

be

printed polycarbonate skin

My

Embedded heneyeeme

Sheet (paper)

Glass fiber

composite

Carbon or Kevlar

remforcemem

Laminated

355 fiber Strips

f

=

;=f :,f:

Glass “W

reinforcement U|tfe|lQhT expanded Compound Glass weave

P0|YSlY|'ef1e foam C0fe layer reinforcement

within honeycomb

Section A-A

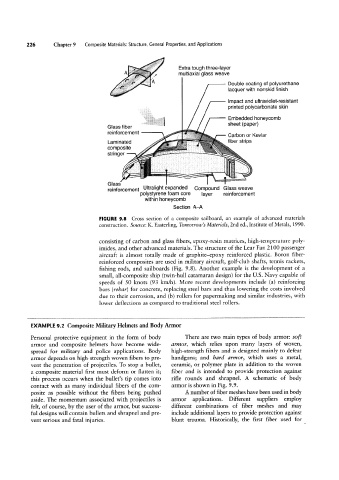

FIGURE 9.8 Cross section of a composite sailboard, an example of advanced materials

construction. Source: K. Easterling, Tomorrou/’s Materials, 2nd ed., Institute of Metals, 1990.

consisting of carbon and glass fibers, epoxy-resin matrices, high-temperature poly-

imides, and other advanced materials. The structure of the Lear Fan 2100 passenger

aircraft is almost totally made of graphite-epoxy reinforced plastic. Boron fiber-

reinforced composites are used in military aircraft, golf-club shafts, tennis rackets,

fishing rods, and sailboards (Fig. 9.8). Another example is the development of a

small, all-composite ship (twin-hull catamaran design) for the U.S. Navy capable of

speeds of 50 knots (93 km/h). More recent developments include (a) reinforcing

bars (rebar) for concrete, replacing steel bars and thus lowering the costs involved

due to their corrosion, and (b) rollers for papermaking and similar industries, with

lower deflections as compared to traditional steel rollers.

EXAMPLE 9.2 Composite Military Helmets and Body Armor

Personal protective equipment in the form of body There are two main types of body armor: soft

armor and composite helmets have become wide- armor, which relies upon many layers of woven,

spread for military and police applications. Body high-strength fibers and is designed mainly to defeat

armor depends on high-strength woven fibers to pre- handguns; and hard armor, which uses a metal,

vent the penetration of projectiles. To stop a bullet, ceramic, or polymer plate in addition to the woven

a composite material first must deform or flatten it; fiber and is intended to provide protection against

this process occurs when the bullet’s tip comes into rifle rounds and shrapnel. A schematic of body

contact with as many individual fibers of the com- armor is shown in Fig. 9.9.

posite as possible without the fibers being pushed A number of fiber meshes have been used in body

aside. The momentum associated with projectiles is armor applications. Different suppliers employ

felt, of course, by the user of the armor, but success- different combinations of fiber meshes and may

ful designs will contain bullets and shrapnel and pre- include additional layers to provide protection against

vent serious and fatal injuries. blunt trauma. Historically, the first fiber used for