Page 271 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 271

250 Chapter 10 Fundamentals of Metal Casting

Surface of

casting Blow Scar Buster

(D) (C)

(H)

Scab _g g Sprue

Wash

Sand mold Gate Misrun

(dl (G) (f)

Gate Gate

Cold shut

(9)

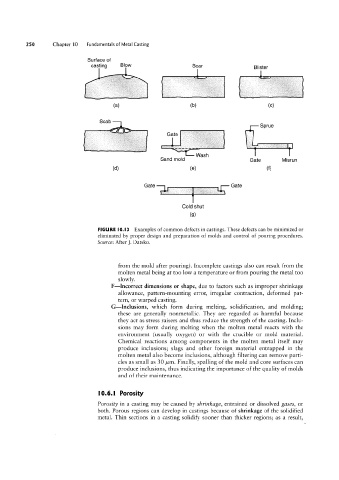

FIGURE l0.I3 Examples of common defects in castings. These defects can be minimized or

eliminated by proper design and preparation of molds and control of pouring procedures.

Source: After ]. Datsko.

from the mold after pouring). Incomplete castings also can result from the

molten metal being at too low a temperature or from pouring the metal too

slowly.

F-Incorrect dimensions or shape, due to factors such as improper shrinkage

allowance, pattern-mounting error, irregular contraction, deformed pat-

tern, or Warped casting.

G-Inclusions, Which form during melting, solidification, and molding;

these are generally nonmetallic. They are regarded as harmful because

they act as stress raisers and thus reduce the strength of the casting. Inclu-

sions may form during melting when the molten metal reacts with the

environment (usually oxygen) or with the Crucible or mold material.

Chemical reactions among components in the molten metal itself may

produce inclusions; slags and other foreign material entrapped in the

molten metal also become inclusions, although filtering can remove parti-

cles as small as 30 um. Finally, spalling of the mold and core surfaces can

produce inclusions, thus indicating the importance of the quality of molds

and of their maintenance.

l0.6.l Porosity

Porosity in a casting may be caused by shrinkage, entrained or dissolved gases, or

both. Porous regions can develop in castings because of shrinkage of the solidified

metal. Thin sections in a casting solidify sooner than thicker regions; as a result,