Page 289 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 289

268 Chapter 11 Metal-Casting Processes and Equipment

\ Pattern ~

Coated

sand

Coated Sand Investment

Pattern

Coated Dump box

sand

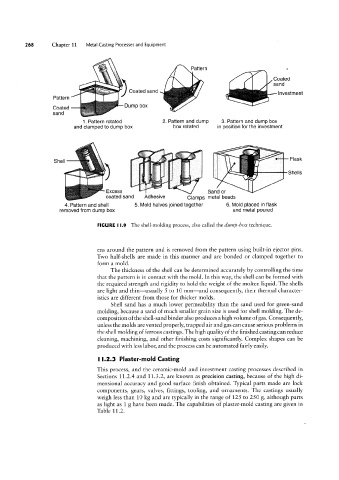

1. Pattern rotated 2. Pattern and dump 3. Pattern and dump box

and clamped to dump box box rotated in position for the investment

'/0

Shell

_g Shells

f

Excess Sandor

coated sand Adhesive C|ampS metal beads

4. Pattern and shell 5. Mold halves joined together 6. l\/lold placed in flask

removed from dump box and metal poured

FIGURE l l.9 The shell-molding process, also called the dump-box technique.

ens around the pattern and is removed from the pattern using built-in ejector pins.

Two half-shells are made in this manner and are bonded or clamped together to

form a mold.

The thickness of the shell can be determined accurately by controlling the time

that the pattern is in contact With the mold. In this way, the shell can be formed with

the required strength and rigidity to hold the Weight of the molten liquid. The shells

are light and thin-usually 5 to 10 mm-and consequently, their thermal character-

istics are different from those for thicker molds.

Shell sand has a much lovver permeability than the sand used for green-sand

molding, because a sand of much smaller grain size is used for shell molding. The de-

composition ofthe shell-sand binder also produces a high volume of gas. Consequently,

unless the molds are vented properly, trapped air and gas can cause serious problems in

the shell molding of ferrous castings. The high quality of the finished casting can reduce

cleaning, machining, and other finishing costs significantly. Complex shapes can be

produced with less labor, and the process can be automated fairly easily.

I l.2.3 Plaster-mold Casting

This process, and the ceramic-mold and investment casting processes described in

Sections 11.2.4 and 11.3.2, are known as precision casting, because of the high di-

mensional accuracy and good surface finish obtained. Typical parts made are lock

components, gears, valves, fittings, tooling, and ornaments. The castings usually

Weigh less than 10 kg and are typically in the range of 125 to 250 g, although parts

as light as 1 g have been made. The capabilities of plaster-mold casting are given in

Table 11.2.