Page 294 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 294

Section 11.3 Expendable-mold, Expendable-pattern Casting Processes 2

I l.3.2 Investment Casting

The investment-casting process, also called the lost-wax process, was first used dur-

ing the period from 4000 to 3000 B.C. Typical parts made are components for office

equipment, as well as mechanical components such as gears, cams, valves, and

ratchets. Parts up to 1.5 m in diameter and weighing as much as 1140 kg have been

cast successfully by this process. The capabilities of investment casting are given in

Table 11.2.

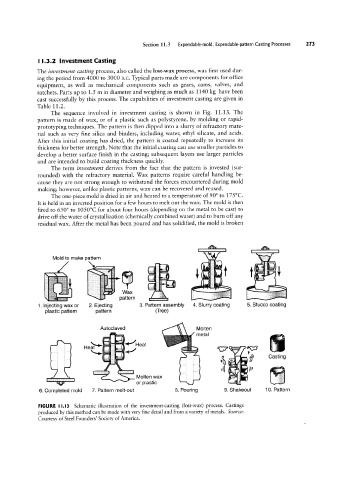

The sequence involved in investment casting is shown in Fig. 11.13. The

pattern is made of wax, or of a plastic such as polystyrene, by molding or rapid-

prototyping techniques. The pattern is then dipped into a slurry of refractory mate-

rial such as very fine silica and binders, including water, ethyl silicate, and acids.

After this initial coating has dried, the pattern is coated repeatedly to increase its

thickness for better strength. Note that the initial coating can use smaller particles to

develop a better surface finish in the casting; subsequent layers use larger particles

and are intended to build coating thickness quickly.

The term investment derives from the fact that the pattern is invested (sur-

rounded) with the refractory material. Wax patterns require careful handling be-

cause they are not strong enough to withstand the forces encountered during mold

making; however, unlike plastic patterns, wax can be recovered and reused.

The one-piece mold is dried in air and heated to a temperature of 90° to 175 °C.

It is held in an inverted position for a few hours to melt out the wax. The mold is then

fired to 650° to 105 0°C for about four hours (depending on the metal to be cast) to

drive off the water of crystallization (chemically combined water) and to burn off any

A

residual wax. After the metal has been poured and has solidified, the mold is broken

T£ Tf5ifi ,

fitf

1

Wax

M;

\ /

it

|\/Iold to make pattern

Il

ffm'

I

4 ff

11:

ff ,i'l' 5:2:;;5'f

~

1

T

ii

. QI

75 ”

> $¢#1 Y¥f

ii!!

~

“

;'§f§

,mid

1*

~”%

.. ..........,,.

2. Ejecting

1. Injecting wax or "" ¢§5;Aé; pattern 3. Pattern assembly 4. Slurry coating 5. Stucco coating

A

plastic pattern pattern (Tree)

Autoclaved |\/|0|ten

'°‘ ....... metal ...a

....

Heat H931 ,...

tai ! 0 Q Q;

'V{, __`4 qptp WWWW ff , _ 9° casting

EW*

Molten lNaX

ev or plastic it

6. Completed mold 7. Pattern melt-out 8. Pouring 9. Snakeout 10. Pattern

FIGURE I l.l3 Schematic illustration of the investment-casting (lost-wax) process. Castings

produced by this method can be made with very fine detail and from a variety of metals. Source:

Courtesy of Steel Founders’ Society of America.