Page 304 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 304

Section 11.4 Permanent-mold Casting Processes 28

“asks I Casting Molten metal

Pouring basin -1

°

and

Qate

Cope

Casting

I\/lold

Q

fi§ifJ§g gg# |||llil

I

lill`|` ,J L,

I

.Egg

Q) Revolving i n

peg

table

(3) (D)

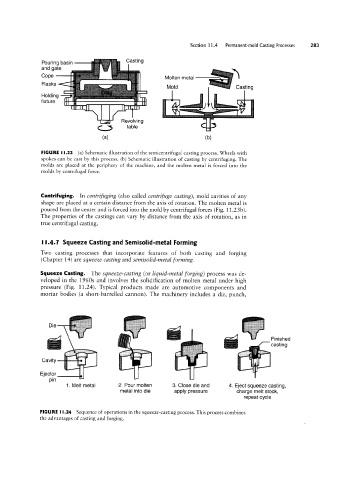

FIGURE I |.23 (a) Schematic illustration of the semicentrifugal casting process. Wheels with

spokes can be cast by this process. (b) Schematic illustration of casting by centrifuging. The

molds are placed at the periphery of the machine, and the molten metal is forced into the

molds by centrifugal force.

Centrifuging. In centrifuging (also called centrifuge casting), mold cavities of any

shape are placed at a certain distance from the axis of rotation. The molten metal is

poured from the center and is forced into the mold by centrifugal forces (Fig. 1 1.23b).

The properties of the castings can vary by distance from the axis of rotation, as in

true centrifugal casting.

I I.4.7 Squeeze Casting and Semisolid-metal Forming

Two casting processes that incorporate features of both casting and forging

(Chapter 14) are squeeze casting and semisolid-metal forming.

Squeeze Casting. The squeeze-casting (or liquid-metal forging) process was de-

veloped in the 1960s and involves the solidification of molten metal under high

pressure (Fig. 11.24). Typical products made are automotive components and

mortar bodies (a short-barrelled cannon). The machinery includes a die, punch,

..ff>ff2¥¥;22é£

A y

Finished

f;r.::; ' mfg,/" Q "f~»--»~~~' casting

;..;;¢;:;.,

- `C‘I“"fT <' mess §2§2¥<f¥¥?i¥¥?i2i;z.;=>=~ i5ii3ffY<€€;1>§%2.;;~ f‘;niixiiiiiEiE<2i;€§33‘ tr .. ...._ fm...

“Eye

Ejector

pin

1. Melt metal 2. Pour molten 3. Close die and 4. Eject squeeze casting,

metal into die apply pressure charge melt stock,

repeat cycle

FIGURE I I.24 Sequence of operations in the squeeze-casting process. This process combines

the advantages of casting and forging.