Page 309 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 309

288 Chapter 11 Metal-Casting Processes and Equipment

slag-forming Constituents). Fluxes are inorganic compounds that refine the molten

metal by removing dissolved gases and various impurities. They may be added man-

ually or Can be injected automatically into the molten metal.

Melting Furnaces. The melting furnaces commonly used in foundries are electric-

arc furnaces, induction furnaces, Crucible furnaces, and cupolas.

° Electric-arc furnaces, described in Section 5.2.3 and illustrated in Fig. 5.2, are

used extensively in foundries and have such advantages as a high rate of melt-

ing (and thus high-production rate), much less pollution than other types of

furnaces, and the ability to hold the molten metal (keep it at a constant tem-

perature for a period of time) for alloying purposes.

° Induction furnaces (Fig. 5.2C) are especially useful in smaller foundries and pro-

duce smaller Composition-controlled melts. There are two basic types. The

coreless induction furnace consists of a Crucible completely surrounded with a

water-Cooled copper coil through which a high-frequency current passes. Because

there is a strong electromagnetic stirring action during induction heating, this

type of furnace has excellent mixing characteristics for alloying and adding a new

charge of metal.

The other type of induction furnace, called a core or channel furnace,

uses a low-frequency Current (as low as 60 Hz) and has a coil that surrounds

only a small portion of the unit. These furnaces commonly are used in nonfer-

rous foundries and are particularly suitable for (a) superheating (that is,

heating above normal Casting temperature to improve fluidity), (b) holding

(which makes it suitable for die-casting applications), and (c) duplexing

(using two furnaces-for instance, melt the metal in one furnace and transfer

it to another).

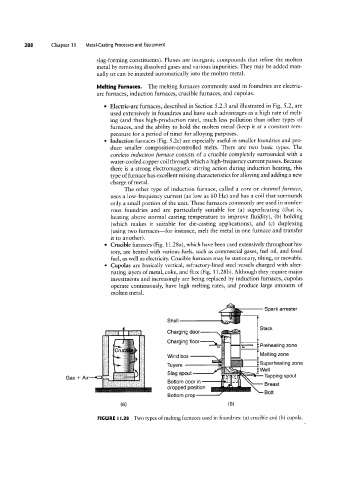

° Crucible furnaces (Fig. 11.28a), which have been used extensively throughout his-

tory, are heated with various fuels, such as commercial gases, fuel oil, and fossil

fuel, as well as electricity. Crucible furnaces may be stationary, tilting, or movable.

° Cupolas are basically vertical, refractory-lined steel vessels charged with alter-

nating layers of metal, coke, and flux (Fig. 1 1.28b). Although they require major

investments and increasingly are being replaced by induction furnaces, cupolas

operate continuously, have high melting rates, and produce large amounts of

shew

molten metal. Charging door Spark arrester

||

fl ___, Stack

rui Ch argmg Cor; ?' Preheating zone

E

E

Wind box

Melting Z0r1e

Slag spout }'“' `

Efggij

§ ~ _ _lweu

oas+/-\ar-»:|,_, Bottom door |n 3 X Tappmgspout

Breast

"

dropped position

Bott

Bottom prop

(a) (D)

FIGURE l.28 Two types of melting furnaces used in foundries: (a) Crucible and (b) cupola.

l