Page 313 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 313

292 Chapter 11 Metal-Casting Processes and Equipment

QUANTITATIVE PROBLEMS

I.39. Estimate the clamping force for a die-casting machine I I.4|. Repeat Problem 11.40, but assume that the aluminum

in which the casting is rectangular with projected dimensions spool is to be cast by expendable-pattern casting. Explain the

of 100 mm >< 175 mm. Would your answer depend on important differences between the two patterns.

whether it is a hot-chamber or cold-chamber process? II.42. In sand casting, it is important that the cope-mold

Explain. half be weighted down with sufficient force to keep it from

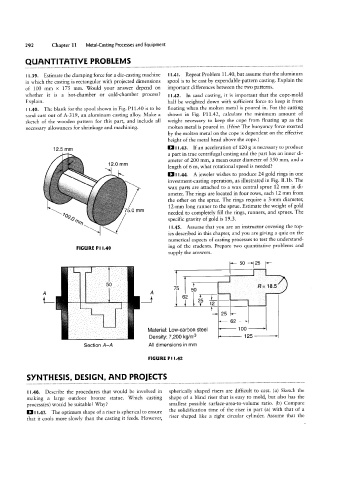

I I.40. The blank for the spool shown in Fig. P11.40 is to be floating when the molten metal is poured in. For the casting

sand cast out of A-319, an aluminum casting alloy. Make a shown in Fig. P11.42, calculate the minimum amount of

sketch of the wooden pattern for this part, and include all weight necessary to keep the cope from floating up as the

necessary allowances for shrinkage and machining. molten metal is poured in. (Hint: The buoyancy force exerted

by the molten metal on the cope is dependent on the effective

height of the metal head above the cope.)

12.5 mm II I I.43. If an acceleration of 120 g is necessary to produce

a part in true centrifugal casting and the part has an inner di-

ameter of 200 mm, a mean outer diameter of 350 mm, and a

120mm

length of 6 m, what rotational speed is needed?

III I.44. A jeweler wishes to produce 24 gold rings in one

investment-casting operation, as illustrated in Fig. II.1b. The

wax parts are attached to a wax central sprue 12 mm in di-

ameter. The rings are located in four rows, each 12 mm from

the other on the sprue. The rings require a 3-mm diameter,

12-mm long runner to the sprue. Estimate the weight of gold

iifi

mm

needed to completely fill the rings, runners, and sprues. The

specific gravity of gold is 19.3.

I |.45. Assume that you are an instructor covering the top-

ics described in this chapter, and you are giving a quiz on the

l 2i5

numerical aspects of casting processes to test the understand-

FIGURE Pl l.40 ing of the students. Prepare two quantitative problems and

supply the answers. [4-50 ->=25|{-

cccc TT"

..

-_‘_ l 62

l

1-.` i,t_ -'-'

-"_

,~>_ .-»_a

"'_- .__‘ __,,,-_ i»'_- _ i 25

-"- f. 62 -l

'»`.-` '-‘-‘.' '»`. |\/Iateriai: Low-carbon steel 100 125

`~_~ ,~",-.1 Q1 '.-' gj '»_"ff

,~l',~,1`

,`~_V',.“

Density: 7,200 kg/m3

Section A-A All dimensions in mm

FIGURE Pl l.42

SYNTHESIS, DESIGN, AND PROIECTS

II.46. Describe the procedures that would be involved in spherically shaped risers are difficult to cast. (a) Sketch the

making a large outdoor bronze statue. Which casting shape of a blind riser that is easy to mold, but also has the

process(es) would be suitable? Why? smallest possible surface-area-to-volume ratio. (b) Compare

D I.47. The optimum shape of a riser is spherical to ensure the solidification time of the riser in part (a) with that of a

I

that it cools more slowly than the casting it feeds. However, riser shaped like a right circular cylinder. Assume that the