Page 317 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 317

296 Chapter 12 Metal Casting: Design, Materials. and Economics

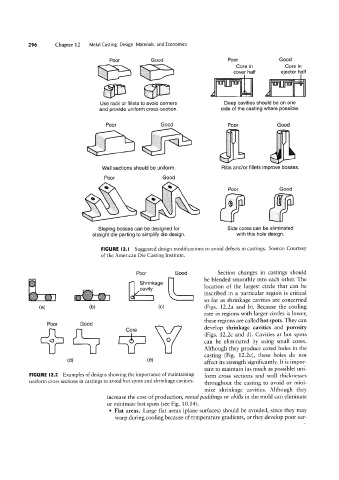

Poor Good Poor Good

Core in Core in

cover half ejector half

all

A

Use radii or fillets to avoid corners Deep cavities should be on one

and provide uniform cross-section. side of the casting where possible.

Poor Good Poor Good

eiialijefe

& Ribs and/or fillets improve bosses.

Wall sections should be uniform.

Good

Poor

Poor

Good

Suggested design modifications to avoid defects in castings. Source: Courtesy

Side cores can be eliminated

Sloping bosses can be designed for

with this hole design.

straight die parting to simplify die design.

FIGURE l2.I

of the American Die Casting Institute.

Section changes in castings should

Good

Poor

be blended smoothly into each other. The

Shrinkage

location of the largest circle that can be

cavity

inscribed in a particular region is critical

so far as shrinkage cavities are concerned

(H) (D) (C) (Figs. 12.2a and b). Because the cooling

rate in regions vvith larger circles is lovver,

these regions are called hot spots. They can

Poor Good

Core develop shrinkage cavities and porosity

(Figs. 12.2c and d). Cavities at hot spots

ff? ,)% f{*F§§7 can be eliminated by using small cores.

Although they produce cored holes in the

casting (Fig. 12.2e), these holes do not

affect its strength significantly. It is impor-

tant to maintain (as much as possible) uni-

FIGURE l2.2 Examples of designs showing the importance of maintaining form cross sections and wall thicknesses

uniform cross sections in castings to avoid hot spots and shrinkage cavities. throughout the casting to avoid or mini-

mize shrinkage cavities. Although they

increase the cost of production, metal paddings or chills in the mold can eliminate

or minimize hot spots (see Fig. 1014).

° Flat areas. Large flat areas (plane surfaces) should be avoided, since they may

Warp during cooling because of temperature gradients, or they develop poor sur-