Page 459 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 459

Section 17.2 Production of Metal Powders

Pressing Coining

Atomization lsostatic pressing Forging

Reduction ROIHIWQ Machining

Electrolytic deposition Extrusion Atmosphere i-ieai treating

plféils comciniggtion Sintermg Secondary

Carbonyls lniection molding Vacuum impregnation

Comminution { Infiltration

Mechanical alloying I Piaiing

'

r

I

-

Hot a2s;i;if:;;@

Lubricants

lsostatid pressing

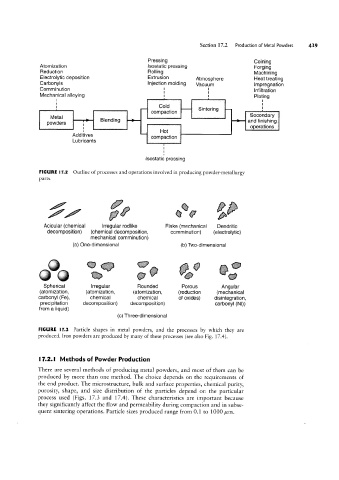

FIGURE l1.2 Outline of processes and operations involved in producing powder-metallurgy

parts.

` ”

Acicular (chemical Irregular rodlike Flake (mechanical Dendritic

decomposition) (chemical decomposition, Comminution) (electrolytic)

mechanical Comminution)

(a) One-dimensional (b) Two-dimensional

Spherical Irregular Rounded Porous Angular

(atomization, (atomization, (atomization, (reduction (mechanical

carbonyl (Fe) chemical chemical of oxides) disintegration

precipitation decomposition) decomposition) carbonyl (Ni)),

from a liquid)

(c) Three-dimensional

FIGURE l7.3 Particle shapes in metal powders, and the processes by which they are

produced. Iron powders are produced by many of these processes (see also Fig. 17.4).

l7.2.| Methods of Powder Production

There are several methods of producing metal powders, and most of them can be

produced by more than one method. The choice depends on the requirements of

the end product. The microstructure, bulk and surface properties, chemical purity,

porosity, shape, and size distribution of the particles depend on the particular

process used (Figs. 17.3 and 17.4). These characteristics are important because

they significantly affect the flow and permeability during compaction and in subse-

quent sintering operations. Particle sizes produced range from 0.1 to 1000 um.