Page 460 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 460

440 Chapter 17 Powder-Metal Processing and Equipment

Q Q Atomization. Atomization involves a

liquid-metal stream produced by injecting

molten metal through a small orifice. The

stream is broken up by jets of inert gas

' or air (Fig. 17.5a) or water (Fig. 17.5b),

known as gas or water atomization, respec-

Q tively. The size and shape of the particles

formed depend on the temperature of the

Q* 1100 pm molten metal, rate of flow, nozzle size, and

_

jet characteristics. The use of water results

(a) (D)

in a slurry of metal powder and liquid at

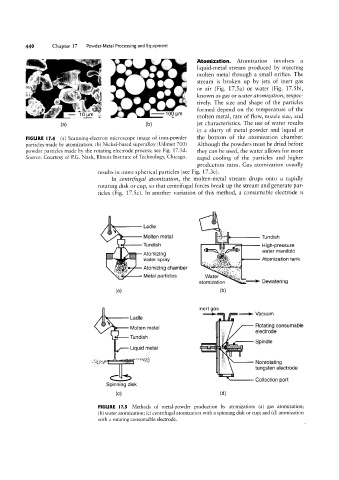

FIGURE l7.4 (a) Scanning-electron microscope image of iron-powder the bottom of the atomization chamber.

particles made by atomization. (b) Nickel-based superalloy (Udimet 700) Although the powders must be dried before

powder particles made by the rotating electrode process; see Fig. 17.5d. they can be used, the water allows for more

Source: Courtesy of PC. Nash, Illinois Institute of Technology, Chicago. rapid cooling of the particles and higher

production rates. Gas atomization usually

results in more spherical particles (see Fig. 17.3c).

In centrifugal atomization, the molten-metal stream drops onto a rapidly

Ladle © <1 1 2 - Tundish

rotating disk or cup, so that centrifugal forces break up the stream and generate par-

ticles (Fig. 17.5c). In another variation of this method, a consumable electrode is

©

Molten metal

E

High-pressure

ma.;

dia /_'

Q Tundish i _ _ water manifold

i-

1

Alomlzing

Water Spray

9:

Atomization tank

__ _ \

A

’

A §ft, x"_$ 5.1

Q ? Atomizing chamber =’.f¢?_`f§;f¥l; Q ff*

V’-sw

Metal particles

Vl/BIBT

il 1* DewaterinQ

atomization L* );¢;%§‘

(21) (D)

m-=1!!-;--

lnert gas

->Vacuum

Ladle --~~r~~

@ Rotating consumable

Molten metal electrode

Nonrotating

Q Tundisn Spindle

/- Liquid metal

tungsten electrode

I

Collection port

Spinning disk

(C) (d)

FIGURE l1.5 Methods of metal-powder production by atomization: (a) gas atomization;

(b) water atomization; (c) centrifugal atomization with a spinning disk or cup; and (d) atomization

with a rotating consumable electrode.