Page 465 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 465

Section 17.3 Compaction of Metal Powders

Upper punch

Shoe i i Shape

Compacted

Powder

Die 5

Lower punch -oo

1. 2. Ejector 4.

3.

Upper punch (G)

‘~ PM spurgear

Lower punch Core rod

(b)

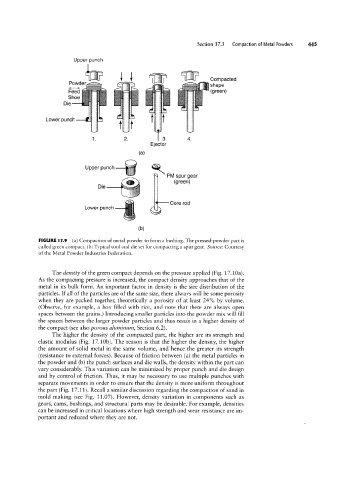

FIGURE l1.9 (a) Compaction of metal powder to form a bushing. The pressed-powder part is

called green compact. (b) Typical tool and die set for compacting a spur gear. Source: Courtesy

of the Metal Powder Industries Federation.

The density of the green compact depends on the pressure applied (Fig. 17.10a).

As the compacting pressure is increased, the compact density approaches that of the

metal in its bulk form. An important factor in density is the size distribution of the

particles. If all of the particles are of the same size, there always will be some porosity

when they are packed together, theoretically a porosity of at least 24% by volume.

(Observe, for example, a box filled with rice, and note that there are always open

spaces between the grains.) Introducing smaller particles into the powder mix will fill

the spaces between the larger powder particles and thus result in a higher density of

the compact (see also porous aluminum, Section 6.2).

The higher the density of the compacted part, the higher are its strength and

elastic modulus (Fig. 17.10b). The reason is that the higher the density, the higher

the amount of solid metal in the same volume, and hence the greater its strength

(resistance to external forces). Because of friction between (a) the metal particles in

the powder and (b) the punch surfaces and die walls, the density within the part can

vary considerably. This variation can be minimized by proper punch and die design

and by control of friction. Thus, it may be necessary to use multiple punches with

separate movements in order to ensure that the density is more uniform throughout

the part (Fig. 17.1 1). Recall a similar discussion regarding the compaction of sand in

mold making (see Fig, 11.07). However, density variation in components such as

gears, cams, bushings, and structural parts may be desirable. For example, densities

can be increased in critical locations where high strength and wear resistance are im-

portant and reduced where they are not.