Page 470 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 470

450 Chapter 17 Powder-Metal Processing and Equipment

for watches, small-caliber gun barrels, scope rings for rifles, door hinges, impellers for

sprinkler systems, and surgical knives.

The major advantages of powder-injection molding over conventional com-

paction are as follows:

° Complex shapes having wall thicknesses as small as 5 mm can be molded and

then removed easily from the dies.

° Mechanical properties are nearly equal to those of wrought products.

° Dimensional tolerances are good.

° High production rates can be achieved by using multicavity dies.

° Parts produced by the PIM process compete well against small investment-cast

parts, small forgings, and complex machined parts. However, the PIM process does

not compete well with zinc and aluminum die casting or with screw machining.

The major limitations of PIM are the high cost and limited availability of fine

metal powders.

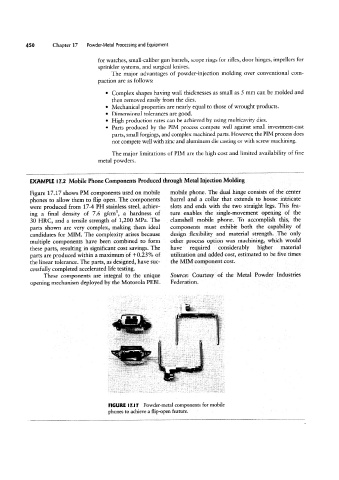

EXAMPLE l7.2 Mobile Phone Components Produced through Metal Injection Molding

Figure 17.17 shows PM components used on mobile mobile phone. The dual hinge consists of the center

phones to allow them to flip open. The components barrel and a collar that extends to house intricate

were produced from 17-4 PH stainless steel, achiev- slots and ends with the two straight legs. This fea-

ing a final density of 7.6 g/cm3, a hardness of ture enables tbe single~movement opening of the

30 HRC, and a tensile strength of 1,200 MPa. The clamshell mobile phone. To accomplish this, the

parts shown are very complex, making them ideal components must exhibit both the capability of

candidates for MIM. The complexity arises because design flexibility and material strength. The only

multiple components have been combined to form other process option was machining, which would

,,;

these parts, resulting in significant cost savings. The have required considerably higher material

parts are produced within a maximum of +0.23% of utilization and added cost, estimated to be five times

the linear tolerance. The parts, as designed, have suc- the MIM component cost.

s" ' [yi ,fp

cessfully completed accelerated life testing.

These components are integral to the unique Source: Courtesy of the Metal Powder Industries

opening mechanism deployed by the Motorola PEBL Federation.

5

4

`~flfi§§55fl3?fif1'5‘f" ; “E”

'f*;§»;» ,,_,;§§j_1§;;»¢fc ,i§§ffl.Ii‘€TI '~»_ .f

>~ >;;,;fe::

fff

“QTL”

"@l:f;;f~f‘1'~1g';_;§,,;i§§‘~i€3ff§§f‘9‘:§f<"’§1

'=ffӤ,

"~“‘~““¥5i

f5.;fi§§§f:fl<?ff5':*?" iff* wil

_l ;‘jj‘ii§££;iI?§g

V77 7 f ’ii'§3f§Wlfji;*' f;f S§5¢f§§§§i=

FIGURE l1.I'I Powder-metal components for mobile

phones to achieve a flip-open feature.