Page 467 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 467

Section 17.3 Compaction of Metal Powders 447

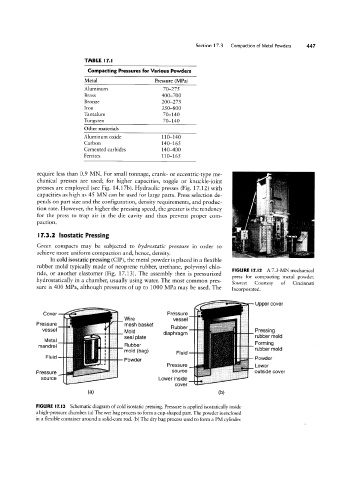

TABLE l7.l

Compacting Pressures for Various Powders

Metal Pressure (MPa)

Aluminum 70-275

Brass 400-700

Bronze 200-275

Iron 350-800

Tantalum 70-140

Tungsten 70-140

Other materials

Aluminum oxide 1 10-140

Carbon 140-165

Cemented carbides 140-400

Ferrites 110-165

require less than 0.9 MN. For small tonnage, crank- or eccentric-type me-

chanical presses are used; for higher capacities, toggle or knuckle-joint

presses are employed (see Fig. 14.17b). Hydraulic presses (Fig. 17.12) with

capacities as high as 45 MN can be used for large parts. Press selection de-

pends on part size and the configuration, density requirements, and produc-

tion rate. However, the higher the pressing speed, the greater is the tendency

for the press to trap air in the die cavity and thus prevent proper com-

paction.

I7.3.2 lsostatic Pressing

Green compacts may be subjected to hydrostatic pressure in order to

achieve more uniform compaction and, hence, density.

In cold isostatic pressing (CIP), the metal powder is placed in a flexible

rubber mold typically made of neoprene rubber, urethane, polyvinyl chlo-

FIGURE l7.l2 A 7.3-MN mechanical

ride, or another elastomer (Fig. 17.13). The assembly then is pressurized

press for compacting metal powder

hydrostatically in a chamber, usually using water. The most common pres-

Source: Courtesy of Cincinnati

sure is 400 MPa, although pressures of up to 1000 MPa may be used. The

Incorporated.

Upper cover

Cover -- Pf€SSUl’€

_ Wire vessel

Pressure _ mesh basket Rubber

Pressing

Vessel _ Mold diaphragm

Meta' _ seal plate rubber mold

Forming

mandrel _ Rubber

lT1Old (bag) |:|uid rubber mold

Flwd _ - Powder Powder

Pressure Lower

Pressure ,_ Source outside cover

source Lower inside

COVGI'

(H)

FIGURE I1.I3 Schematic diagram of cold isostatic pressing. Pressure is applied isostatically inside

a high-pressure chamber (a) The wet bag process to form a cup-shaped part. The powder is enclosed

in a flexible container around a solid-core rod. (b) The dry bag process used to form a PM cylinder