Page 471 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 471

Section 17.3 Compaction of Metal Powders

Forging. In powder forging (PF), the part produced from compaction and sintering

serves as the preform in a hot-forging operation. These products are almost fully

dense and have a good surface finish, good dimensional tolerances, and a uniform

and fine grain size. The superior properties obtained make forging particularly suit-

able for such applications as highly stressed automotive (such as connecting rods)

and jet-engine components.

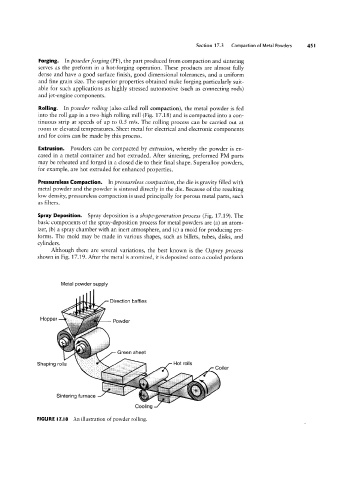

Rolling. In powder rolling (also called roll compaction), the metal powder is fed

into the roll gap in a two-high rolling mill (Fig. 17.18) and is compacted into a con-

tinuous strip at speeds of up to 0.5 m/s. The rolling process can be carried out at

room or elevated temperatures. Sheet metal for electrical and electronic components

and for coins can be made by this process.

Extrusion. Powders can be compacted by extrusion, whereby the powder is en-

cased in a metal container and hot extruded. After sintering, preformed PM parts

may be reheated and forged in a closed die to their final shape. Superalloy powders,

for example, are hot extruded for enhanced properties.

Pressureless Compaction. In pressureless compaction, the die is gravity filled with

metal powder and the powder is sintered directly in the die. Because of the resulting

low density, pressureless compaction is used principally for porous metal parts, such

as filters.

Spray Deposition. Spray deposition is a shape-generation process (Fig. 17.19). The

basic components of the spray-deposition process for metal powders are (a) an atom-

HODDGY Direction baffles

izer, (b) a spray chamber with an inert atmosphere, and (c) a mold for producing pre-

forms. The mold may be made in various shapes, such as billets, tubes, disks, and

cylinders.

Although there are several variations, the best known is the Osprey process

shown in Fig. 17.19. After the metal is atomized, it is deposited onto a cooled preform

Metal powder supply

,,‘

Powder

iiii

Shaping rolls Green sheet pppy HOT V0|lS Coiler

Sintering furnace

Cooling

FIGURE |1.l8 An illustration of powder rolling.