Page 475 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 475

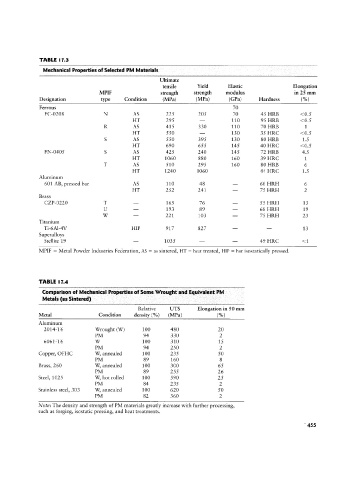

TABLE l1.3

Mechanical Properties of Selected PM Materials

Ultimate

tensile Yield Elastic Elongation

MPIF strength strength modulus in 25 mm

Designation type Condition (MPa) (MPa) (GPa) Hardness (%)

Ferrous 70

FC-0208 N AS 225 205 70 45 HRB <0.5

HT 295 - 110 95 HRB <0.5

R AS 415 330 110 70 HRB 1

HT 550 - 130 35 HRC <0.5

S AS 550 395 130 80 HRB 1.5

HT 690 655 145 40 HRC <0.5

FN-0405 S AS 425 240 145 72 HRB 4.5

HT 1060 880 160 39 HRC 1

T AS 510 295 160 80 HRB 6

HT 1240 1060 44 HRC 1.5

Aluminum

-

601 AB, pressed bar AS 110 48 - 60 HRH 6

HT 252 241 75 HRH 2

Brass

CZP-0220 T - 165 76 - 55 HRH 13

-

U - 193 89 - 68 HRH 19

W - 221 103 75 HRH 23

Titanium

Ti-6Al-4V HIP 917 827 - - 13

Superalloys

Stellite 19 - 1035 - - 49 HRC <1

MPIF = Metal Powder Industries Federation, AS = as sintered, HT 1 heat treated, HIP = hot isostatically pressed.

TABLE I1.4

Comparison of Mechanical Properties of Some Wrought and Equivalent PM

Metals (as Sintered)

Relative UTS Elongation in 5 0 mm

Metal Condition density (%) (MPa) (%)

Aluminum

2014-T6 Wrought (W) 100 480

PM 94 330

6061-T6 W 100 310

PM 94 250

Copper, OFHC W, annealed 100 235

PM 89 160

Brass, 260 W annealed 100 300

PM 89 255

Steel, 1025 W, hot rolled 100 590

PM 84 235

Stainless steel, 303 W, annealed 100 620

PM 82 360

Note: The density and strength of PM materials greatly increase with further processing,

such as forging, isostatic pressing, and heat treatments.

455