Page 479 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 479

Section 17.7 Process Capabilities

.e e ,

f

Good

G00d

Poor

P00|'

Radius forease I EX) r

Thicker flange

I

f

._

Radius to reduce

O_2H

f

ei \, /likelihood of chipping , . , "" to-15/‘f max)

(fi) (D)

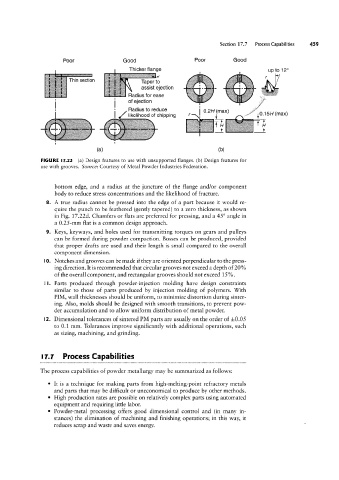

FIGURE |7.23 (a) Design features to use with unsupported flanges. (b) Design features for

use with grooves. Source: Courtesy of Metal Powder Industries Federation.

bottom edge, and a radius at the juncture of the flange and/or component

body to reduce stress concentrations and the likelihood of fracture.

8. A true radius cannot be pressed into the edge of a part because it would re-

quire the punch to be feathered (gently tapered) to a zero thickness, as shown

in Fig. 17.22d. Chamfers or flats are preferred for pressing, and a 45° angle in

a 0.25 -mm flat is a common design approach.

9. Keys, keyways, and holes used for transmitting torques on gears and pulleys

can be formed during powder compaction. Bosses can be produced, provided

that proper drafts are used and their length is small compared to the overall

component dimension.

I0. Notches and grooves can be made if they are oriented perpendicular to the press-

ing direction. It is recommended that circular grooves not exceed a depth of 20%

of the overall component, and rectangular grooves should not exceed 15%.

ll. Parts produced through powder-injection molding have design constraints

similar to those of parts produced by injection molding of polymers. With

PIM, wall thicknesses should be uniform, to minimize distortion during sinter-

ing. Also, molds should be designed with smooth transitions, to prevent pow-

der accumulation and to allow uniform distribution of metal powder.

I2. Dimensional tolerances of sintered PM parts are usually on the order of i0.05

to 0.1 mm. Tolerances improve significantly with additional operations, such

as sizing, machining, and grinding.

l7.7 Process Capabilities

The process capabilities of powder metallurgy may be summarized as follows:

It is a technique for making parts from high-melting-point refractory metals

and parts that may be difficult or uneconomical to produce by other methods.

High production rates are possible on relatively complex parts using automated

equipment and requiring little labor.

Powder-metal processing offers good dimensional control and (in many in-

stances) the elimination of machining and finishing operations; in this way, it

reduces scrap and waste and saves energy.