Page 478 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 478

Chapter 17 Powder-Metal Processing and Equipment

Poor Good

oooooo QT P G d

E al? E OO F

Finer radius

F

.

cor

Fillet radius

Sharp radius

e oo . .

Sharp radius

ii

ii

Sharp can be

Must be

(H) sa t. (D) radius

B

Fillet

5

s

ra ius sr F?

punch Die _,1 Sharp radius er-§=>§

0.25 mm

(min)

Upper

Fillet

Feather edge

radius

té 5

required on

s as

E é

Workpiece punch (C) .r id) §§ .

-ef

Acceptable Best Acceptable with additional operations

Die Punch 0-25_mm -4 -

ee

(min) /§eo°-45°

workpiece W Hole must Thread must be

be drilled machined

(9) (f)

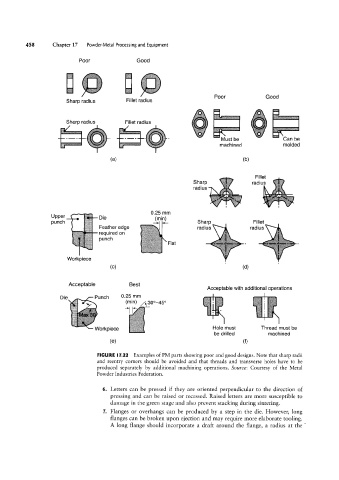

FIGURE l7.22 Examples of PM parts showing poor and good designs. Note that sharp radii

and reentry corners should be avoided and that threads and transverse holes have to be

produced separately by additional machining operations. Source: Courtesy of the Metal

Powder Industries Federation.

6. Letters can be pressed if they are oriented perpendicular to the direction of

pressing and can be raised or recessed. Raised letters are more susceptible to

damage in the green stage and also prevent stacking during sintering.

7. Flanges or overhangs can be produced by a step in the die. However, long

flanges can be broken upon ejection and may require more elaborate tooling.

A long flange should incorporate a draft around the flange, a radius at the