Page 664 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 664

Section 23.5

ga

too large an angle can cause chipping or E,

g

breaking of the cutting edge. In addition to 2° E E

':

conventional point drills, several other O) g 'E

drill-point geometries have been developed 9 E Y; ‘g g .2

to improve drill performance and increase 'E 8 53 8 8 gg 8 High-pressure

the penetration rate. Special grinding tech- coolant

niques and equipment are used to produce

these geometries.

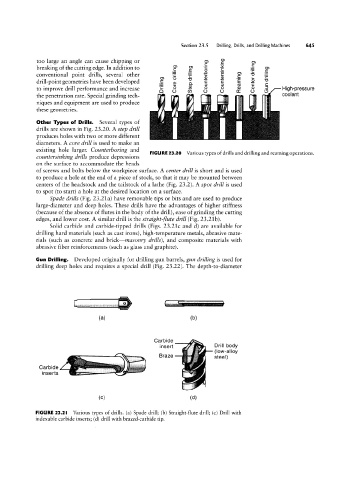

Other Types of Drills. Several types of

drills are shown in Fig. 23.20. A step drill

produces holes with two or more different

diameters. A core drill is used to make an

existing hole larger. Counterboring and

FIGURE 23.20 Various types of drills and drilling and reaming operations.

countersinking drills produce depressions

on the surface to accommodate the heads

of screws and bolts below the workpiece surface. A center drill is short and is used

to produce a hole at the end of a piece of stock, so that it may be mounted between

centers of the headstock and the tailstock of a lathe (Fig. 23.2). A spot drill is used

to spot (to start) a hole at the desired location on a surface.

Spade drills (Fig. 23.21a) have removable tips or bits and are used to produce

large-diameter and deep holes. These drills have the advantages of higher stiffness

(because of the absence of flutes in the body of the drill), ease of grinding the cutting

edges, and lower cost. A similar drill is the straight-flute drill (Fig. 23.21b).

Solid carbide and carbide-tipped drills (Figs. 23.21c and d) are available for

drilling hard materials (such as cast irons), high-temperature metals, abrasive mate-

rials (such as concrete and brick-masonry drills), and composite materials with

abrasive fiber reinforcements (such as glass and graphite).

Camei

Gun Drilling. Developed originally for drilling gun barrels, gun drilling is used for

drilling deep holes and requires a special drill (Fig. 23.22). The depth-to-diameter

’é"""3\&

(D)

(G) insert

Braze

o .

Carbide

Drill body

(lowlalloy

..._

.fi

inserts ....... ..... , .,,..,. (vi,

,_

(C) (fi)

FIGURE 23.2I Various types of drills. (a) Spade drill; (b) Straight-flute drill; (c) Drill with

indexable carbide inserts; (d) drill with brazed-carbide tip.

S

:.

§

9°

YJ

:_

F

Q)

:a

cz.

U

:.

ET

und

rilling

un

§

Q1

(5

Ei

:s

(D

U)

¢\

-5

U\