Page 97 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 97

Chapter 2 Mechanical Behavior, Testing, and Manufacturing Properties of Materials

Scale

Pendulum End of S

Specimen P Starting position

(1o><1o><55mm)

Q

pecimen

Hammer

-

Swing Anvil Specimen (1O><1O><75mm)

r

Notch gc Penduium

Izod kk H 1;

(H) (bl

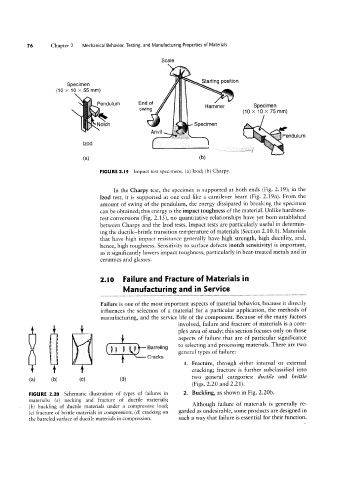

FIGURE 2.l9 Impact test specimens. (a) Izod; (bl Charpy.

In the Charpy test, the specimen is supported at both ends (Fig. 2.19); in the

Izod test, it is supported at one end like a cantilever beam (Fig. 2.19a). From the

amount of swing of the pendulum, the energy dissipated in breaking the specimen

can be obtained; this energy is the impact toughness of the material. Unlike hardness-

test conversions (Fig. 2.15 ), no quantitative relationships have yet been established

between Charpy and the Izod tests. Impact tests are particularly useful in determin-

ing the ductile-brittle transition temperature of materials (Section 2.10.1). Materials

that have high impact resistance generally have high strength, high ductility, and,

hence, high toughness. Sensitivity to surface defects (notch sensitivity) is important,

as it significantly lowers impact toughness, particularly in heat-treated metals and in

ceramics and glasses.

2.l0 Failure and Fracture of Materials in

Manufacturing and in Service

Failure is one of the most important aspects of material behavior, because it directly

influences the selection of a material for a particular application, the methods of

manufacturing, and the service life of the component. Because of the many factors

involved, failure and fracture of materials is a com-

plex area of study; this section focuses only on those

aspects of failure that are of particular significance

to selecting and processing materials. There are two

op 0 9 Barreiing

general types of failure:

Cracks

I. Fracture, through either internal or external

cracking; fracture is further subclassified into

two general categories: ductile and brittle

(3) (bl (C) (dl

(Figs. 2.20 and 2.21).

FIGURE 2.20 Schematic illustration of types of failures in 2. Buckling, as shown in Fig. 2.20b.

materials: (a) necking and fracture of ductile materials;

(b) buckling of ductile materials under a compressive load; Although failure of materials is generally re-

(c) fracture of brittle materials in compression; (d) cracking on garded as undesirable, some products are designed in

the barreled surface of ductile materials in compression. such a way that failure is essential for their function.