Page 155 - Marine Structural Design

P. 155

Chapter 7 Limit State Design of qffshore Structures 131

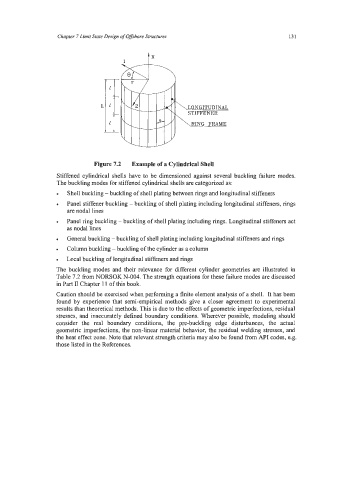

Figure 7.2 Example of a Cylindrical Shell

Stiffened cylindrical shells have to be dimensioned against several buckling failure modes.

The buckling modes for stiffened cylindrical shells are categorized as:

Shell buckling - buckling of shell plating between rings and longitudinal stiffeners

Panel stiffener buckling - buckling of shell plating including longitudinal stiffeners, rings

are nodal lines

Panel ring buckling - buckling of shell plating including rings. Longitudinal stiffeners act

as nodal lines

General buckling -buckling of shell plating including longitudinal stiffeners and rings

Column buckling - buckling of the cylinder as a column

Local buckling of longitudinal stiffeners and rings

The buckling modes and their relevance for different cylinder geometries are illustrated in

Table 7.2 from NORSOK N-004. The strength equations for these failure modes are discussed

in Part II Chapter 11 of this book.

Caution should be exercised when performing a finite element analysis of a shell. It has been

found by experience that semi-empirical methods give a closer agreement to experimental

results than theoretical methods. This is due to the effects of geometric imperfections, residual

stresses, and inaccurately defined boundary conditions. Wherever possible, modeling should

consider the real boundary conditions, the pre-buckling edge disturbances, the actual

geometric imperfections, the non-linear material behavior, the residual welding stresses, and

the heat effect zone. Note that relevant strength criteria may also be found from API codes, e.g.

those listed in the References.